DGSMARTWIN KYAC2000 Series: Benchmark of Coreless Direct Drive for Light-Load and High-Speed Scenarios

In the field of light-load, high-speed and precision transmission, the in-depth application of coreless technology has become the key to breaking through performance bottlenecks. The dgsmartwin KYAC2000 Series coreless linear motors have become the preferred power solution for micro automated equipment with precise parameter calibration and core technical advantages.

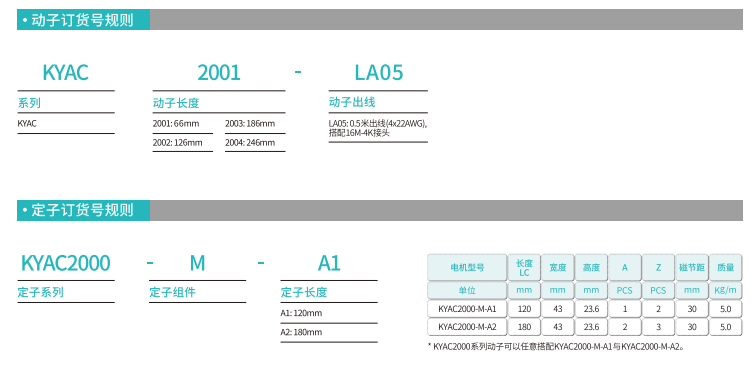

To adapt to the personalized needs of different equipment, the KYAC2000 Series provides a variety of modular configuration options:

Optional mover length:Supports four specifications: 2001 (66mm), 2002 (126mm), 2003 (186mm), and 2004 (246mm), which can be flexibly matched according to thrust requirements.

Stator length adaptation:Provides two stator lengths, A1 (120mm) and A2 (180mm). The mover can be arbitrarily matched with the two stator components to meet different stroke requirements.

Customizable outlet method:Standard configuration with LA05 outlet solution, including 0.5-meter cable and 16M-4K connector, simplifying equipment wiring and maintenance.

With the characteristics of no cogging, high dynamics and compact volume, the KYAC2000 Series has become a key power unit in many fields:

Precision electronic assembly:Realizes high-speed and smooth positioning movement in the mounting and insertion equipment of small components of 3C products, avoiding component damage.

Medical equipment:Ensures the smoothness of movement and positioning accuracy in the sample transmission of diagnostic equipment and the drive of detection platforms.

High-speed sorting system:Realizes rapid start-stop and precise trajectory control in high-speed sorting equipment for small materials, improving sorting efficiency.

Optical detection equipment:Provides jitter-free dynamic movement support for lenses or detection platforms in visual inspection and laser scanning equipment.

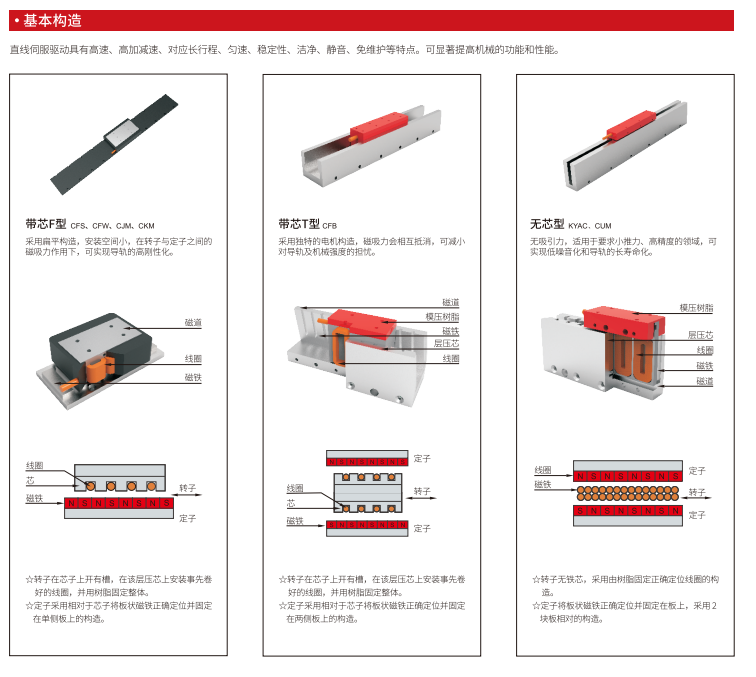

The core competitiveness of the KYAC2000 Series stems from the in-depth insight into the needs of light-load and high-speed scenarios and the implementation of technical differentiation. Compared with traditional iron-core motors, its coreless hollow coil structure greatly reduces the mover mass, fundamentally eliminating the cogging effect, and the motion smoothness is far superior to that of iron-core products of the same specification; at the same time, the dual-magnetic-rail balance design has no magnetic attraction interference, simplifying the installation and alignment process. Combined with the potting and sealing process, it improves environmental adaptability, balancing protection and heat dissipation efficiency. Its parameter gradient layout and modular selection logic not only avoid cost waste caused by "power redundancy", but also accurately match different light-load working conditions. Its performance is comparable to that of international first-tier brands, and it has more advantages in delivery time and cost, becoming the core power support for the upgrading of micro precision equipment and demonstrating dgsmartwin's in-depth technical strength in the field of coreless direct drive.

En

En