DGSMARTWIN CKM050 Series: Motor Manufacturer Recommendation - Deeply Engaged in Direct Drive Technology

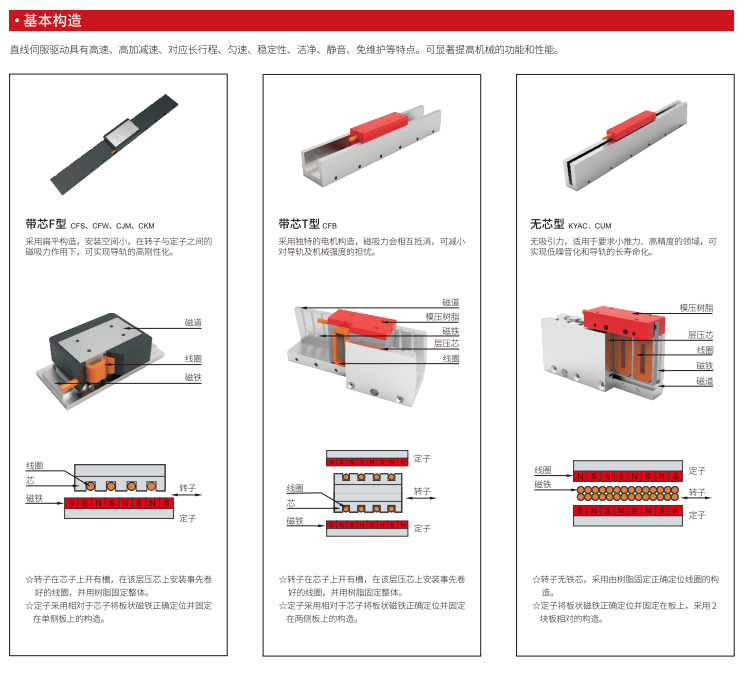

In the field of industrial automation, facing the dual demands of heavy load and high dynamic response, the dgsmartwin CKM050 Series iron-core linear motors have become a reliable choice for driving heavy-duty precision motion, relying on their iron-core technology and high-rigidity structure.

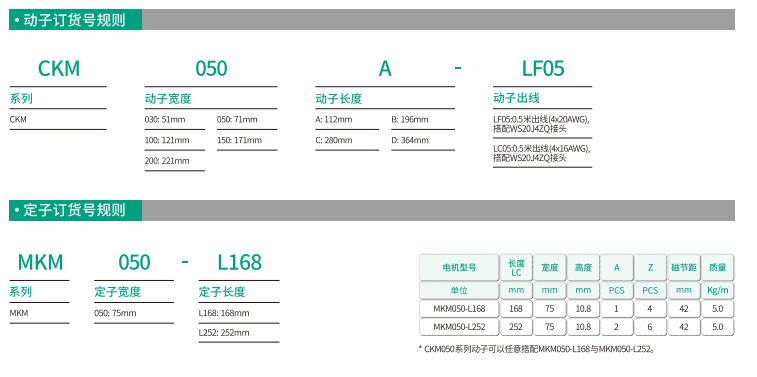

The parameters of this series are professionally calibrated with clear gradients, perfectly meeting the needs of medium-load scenarios: the mover width covers multiple specifications of 51/71/121/171/221mm, and the length is divided into four grades A/B/C/D as 112/196/280/364mm, adapting to the spatial layout of different equipment; in terms of power output, the performance differences of sub-models are clear: CKM050A has a continuous thrust of 176N and a peak thrust of 396N, while CKM050C has a continuous thrust of 526N and a peak thrust of 1188N, allowing precise model selection according to load requirements. The core selling points inherit the technical advantages of the series: ultra-low cogging force is achieved through optimized magnetic circuit design, and the thrust fluctuation is controlled at the optimal level among products of the same specification; the high-rigidity structure combined with the close coupling of the iron core and the coil significantly improves the electromagnetic conversion efficiency; the lower back EMF design ensures stability during high-speed operation. Compared with conventional iron-core motors, it locks the positioning accuracy at the micron level while outputting strong power, solving the industry pain point of "loss of precision in medium-load applications".

Relying on precise parameters and core selling points, the CKM050 Series has achieved precise value implementation in medium-load precision scenarios, adapting to diverse high-demand working conditions. In the field of new energy battery manufacturing, its peak thrust can stably drive the transfer mechanism of medium-sized battery cell modules; the high-rigidity structure effectively offsets the vibration caused by high-speed start and stop, avoiding battery cell collision damage; it is suitable for the medium-distance handling process after pole piece cutting, ensuring the flatness of the pole piece edge. In medium-sized laser precision cutting scenarios, the ultra-low cogging force feature supports the uniform movement of the laser cutting head; combined with micron-level positioning accuracy, even when cutting medium-thickness metal plates, the edge roughness can be reduced to meet the needs of precision processing. In addition, in the medium-load execution link of heavy-duty positioning platforms, the multi-specification movers of the CKM050 Series can flexibly adapt to the frame design; the standardized mounting hole layout, combined with the precise adaptation of the stator (model format: MKM 050 - L168), can be integrated without major modifications; the continuous and stable thrust output can drive the tooling platform to operate efficiently for a long time; the direct drive structure with no mechanical wear further extends the equipment maintenance cycle.

The core competitiveness of the CKM050 Series stems from the in-depth insight into the needs of medium-load scenarios and the implementation of technical differentiation, demonstrating dgsmartwin's profound strength in the direct drive field. Compared with the CKM030 light-load model in the series, its thrust density is significantly improved, capable of meeting higher load requirements; compared with the CKM200 heavy-load model, it adapts to small and medium-sized equipment with a more compact volume, avoiding power redundancy and space waste. Compared with the traditional lead screw drive solution, the direct drive structure of this series completely eliminates mechanical backlash, significantly improving positioning accuracy and response speed, and reducing operation and maintenance costs by more than 40%. Relying on dgsmartwin's national-level specialized, refined, characteristic and new technology accumulation, this series has passed strict working condition verification and has been widely used by leading enterprises in new energy, laser processing and other fields. It not only inherits the reliable quality of the CKM series, but also becomes a key power support for promoting the automation upgrade of medium-load precision equipment with its medium-load exclusive parameters and performance advantages.

En

En