Dongguan SMARTWIN lntelligent Equipment Co.,Ltd.: Empowering the Upgrade of High-End Manufacturing Clusters with Systematic Precision Direct Drive Solutions

DGSMARTWIN Intelligent Equipment: Empowering the Upgrade of High-End Manufacturing Clusters with Systematic Precision Direct Drive Solutions

Amid the global trend of manufacturing transformation toward intelligence and precision, the performance of motion control systems has become a core bottleneck for high-end equipment. Traditional transmission technologies are approaching their physical limits, and direct drive technology has emerged as the key to breaking through this impasse, thanks to its advantages of "zero mechanical transmission and high dynamic response". As one of the few domestic enterprises with an independent full-chain layout covering "core components, control systems, and feedback systems", DGSMARTWIN not only provides high-performance core products such as linear motors but also builds a comprehensive precision direct drive technology ecosystem. By integrating self-developed high-precision encoders, drives, and various actuators, the company lays a solid underlying power foundation for national strategic industries such as new energy lithium batteries and semiconductors, serving as a core force driving the upgrade of China's intelligent manufacturing infrastructure.

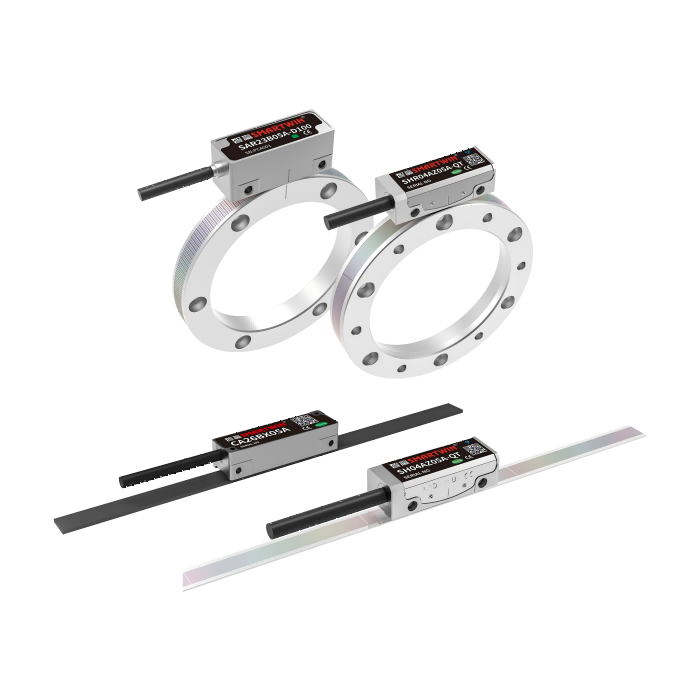

DGSMARTWIN's core technological barriers and market competitiveness are concentrated in its ability to build a complete technology stack from "component innovation" to "system value closed loop". At the core component level, the company achieves 100% independent controllability: the self-developed SH04 grating encoder has a resolution of 1.0μm/0.5μm/0.1μm, and the SA32 grating encoder has a resolution of 0.05μm/0.1μm, whose performance can match that of international first-tier brands; the AKS series drives are compatible with multiple bus and pulse command protocols, and embedded with adaptive control algorithms to meet the needs of complex working conditions; key indicators of linear motor products, such as thrust density and maximum operating speed (5m/s), are at the leading level in the industry, completely breaking the technical and product monopoly of overseas suppliers.

Supported by solid core components, DGSMARTWIN has built a product matrix covering all application scenarios of precision direct drive: it includes high-power drive solutions adapted to heavy-duty and long-stroke working conditions, and can also meet the special operation needs of high speed and high precision in clean environments; it can achieve extremely smooth and zero-interference micro-motion control, and also provide rotary application solutions for high-torque direct rotary drive. The full-scenario product portfolio built on a unified technology platform helps customers obtain synergistically optimized and seamlessly integrated system-level performance, rather than a simple superposition of isolated components, maximizing the application value of direct drive technology.

Deeper industry empowerment stems from DGSMARTWIN's in-depth scenario-based development model of "co-defining products with customers" and its full-life-cycle service system. In the new energy lithium battery industry, DGSMARTWIN's linear motor modules and DD motors are deeply integrated into core process links such as battery cells and PACK. Relying on high rigidity and high acceleration characteristics, they significantly improve production line operation tact and product yield. In the field of semiconductor and panel manufacturing, the company's coreless linear motors fundamentally eliminate the interference of cogging force on scanning precision, and the fully enclosed protection modules solve the problem of stable operation of core motion components in Class 1000 or even Class 100 clean rooms.

En

En