DGSMARTWIN DH04 Series: Precise Parameters of Modular Torque Motors

In the field of precision control for industrial automation, torque motors are the core components for achieving high-dynamic and high-precision rotary motion. The DH04 series modular torque motors launched by dgsmartwin provide reliable solutions for applications requiring precise angle control, thanks to their compact design and strong performance.

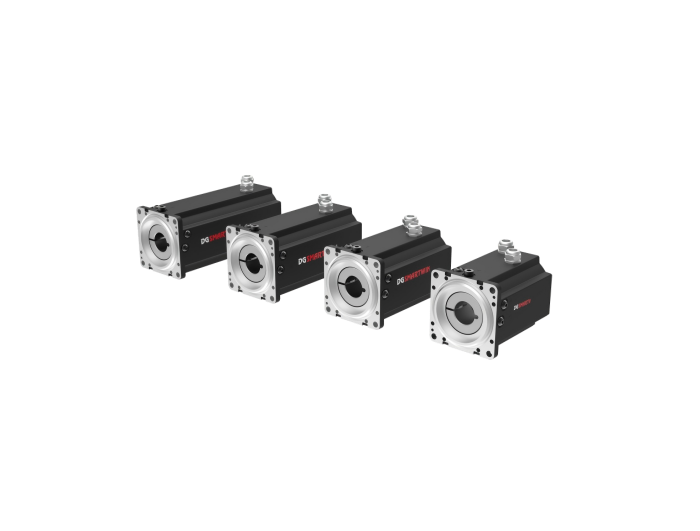

The core parameters of this series cover the full range of medium and low load requirements with professional and accurate technical specifications. In terms of torque output, the continuous torque stably ranges from 4.1 N·m (DH041 sub-model) to 13.9 N·m (DH044 sub-model), with corresponding peak torque from 12.1 N·m to 39.2 N·m, enabling precise matching for different load demands. In structural size, frame size 04 corresponds to a compact 108 mm specification, and the body length is optimized in gradient according to torque levels, perfectly fitting space-constrained equipment.

Relying on precise parameters and core selling points, the DH04 series realizes value implementation in diverse segmented scenarios, with its parameter advantages precisely matching application requirements:

· Precision machine tools: Achieves micron-level angle positioning in CNC rotary tables and tool magazine drives, improving machining accuracy.

· Robot joints: Provides high-dynamic torque output for joints of collaborative robots and SCARA robots, ensuring smooth motion.

· Automated inspection: Realizes high-speed start-stop and precise angle positioning on rotary platforms of visual inspection equipment.

·

The core competitiveness of the DH04 series stems from the scenario-specific parameter design and differentiated advantages of technical features. Compared with traditional torque motors, this series breaks the extensive mode of "one model for multiple scenarios" with "precise parameter gradients + modular configuration". The torque and size gradients of the four sub-models allow users to select models accurately without redundancy. The modular architecture simplifies installation, and standardized interfaces can quickly connect to mainstream control systems, shortening commissioning cycles.

In terms of performance:Its high torque density design delivers strong power output within a limited space;Low cogging effect, achieved by optimizing magnetic circuit and winding layout, ensures smooth and ripple-free operation at low speeds;High dynamic response enables the motor to follow commands rapidly, enhancing system agility.

Meanwhile, the direct load connection eliminates intermediate transmission parts such as gearboxes, reducing maintenance costs and eliminating backlash. Combining zero backlash and load compliance technology, the position and speed control accuracy of the motor is significantly improved.

Notably, it balances parameter precision and cost control, with performance comparable to international counterparts, while customized costs are reduced by more than 50% and lead times are more controllable.

As another masterpiece of dgsmartwin manufacturing, the DH04 series modular torque motors break the performance boundaries of traditional rotary drives with the characteristics of "small size, high torque, and high flexibility". In the wave of intelligent manufacturing upgrades, it is not only the core support for equipment miniaturization and high precision, but also a key partner for enterprises to improve equipment performance and optimize space layout.

En

En