SMARTWIN CFS055 Series: Independent R&D Builds a Precision Power Benchmark for Multiple Scenarios

Amid the wave of intelligent manufacturing, linear motors serve as core power components, and striking a balance between performance and cost has long been a pursuit of the industry. Against this backdrop, the CFS055 Series Iron-Core Linear Motors developed by SMARTWIN emerge as a highly competitive product. Positioned primarily as a cost-effective solution, it perfectly integrates the performance advantages of iron-core technology with high cost-efficiency, offering a superior option for automation equipment manufacturers.

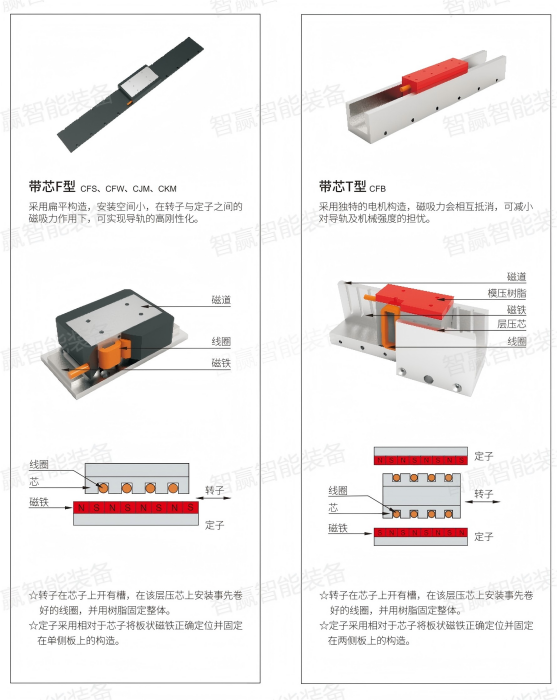

The core of the CFS055 Series lies in its adoption of proven iron-core technology, which inherently ensures low fluctuation and precise control during high-speed operation from the bottom layer of electromagnetic design, making it ideally suited for the stringent working conditions of high-speed and high-precision equipment. Meanwhile, the series is engineered with low cogging force, effectively reducing vibration and noise during motor operation to guarantee motion stability—a feature critical for applications requiring high-precision positioning. What deserves more attention is that the integration of standardized modular design and one-piece injection molding technology significantly improves product consistency and boosts production efficiency by 70% compared with industry peers, establishing core competitiveness in both performance and supply chain efficiency.

The launch of the CFS055 Series holds profound significance for the industry. It lowers the application threshold of high-performance linear motors, enabling more automation equipment—especially those in the mid-to-low-end market—to benefit from the performance improvements brought by linear motors. For instance, in 3C electronics assembly lines, food and pharmaceutical packaging lines, and certain testing equipment, the CFS055 Series can replace traditional ball screw drives, enhancing speed and precision while reducing maintenance costs to create greater value for end users. In semiconductor manufacturing processes, the series’ high-speed and low-fluctuation operation allows wafer transfer robotic arms to complete handling tasks at a higher beat, and its maintenance-free nature drastically cuts equipment downtime in clean rooms. In general-purpose automation equipment, the standardized modular design eliminates the need for customized development during equipment integration, significantly shortening the R&D cycle and serving as an efficient power support for the upgrading of automated production lines.

The CFS055 Series is a tangible embodiment of SMARTWIN’s philosophy of "empowering scenario upgrading with independent technology". Its fully independently developed core technologies break the technical monopoly of foreign brands in the field of precision linear motors, allowing the products to match the performance of international first-tier brands while boasting more controllable delivery times and better cost advantages. The full coverage of specifications, sizes and thrust levels stems from an in-depth insight into the needs of multiple sectors such as new energy, 3C electronics and semiconductors, achieving an efficient solution of "one series for multiple scenarios". Moreover, the technological innovations in standardized modularization and one-piece injection molding not only improve product stability, but also reduce the costs of equipment selection, integration, operation and maintenance for enterprises. Compared with traditional transmission solutions, the direct-drive structure of the CFS055 Series eliminates mechanical gaps and wear risks, increasing the mean time between failures (MTBF) of equipment by more than twice. For manufacturing enterprises pursuing high precision, high efficiency and low cost, the CFS055 Series is more than just a power component—it is a core support for driving equipment upgrading and enhancing industrial competitiveness.

En

En