DGSMARTWIN CMW060 Series: Powerful Power in Compact Space

Under the trend of miniaturization and high-speed of automation equipment, how to output sufficient thrust in limited space while ensuring stable movement is a problem faced by many equipment engineers. The dgsmartwin CMW060 Series iron-core linear motors are high-adaptability solutions designed to solve this pain point.

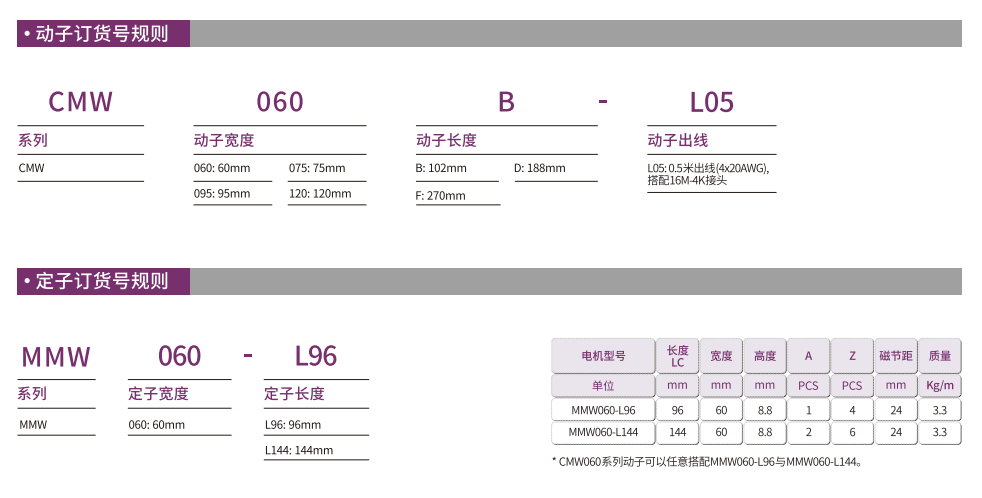

The parameters of this series are professionally calibrated with clear gradients, fully covering the demands of medium-load working conditions: in terms of structure, the mover width ranges from 60mm to 120mm, and the length is divided into three gradients B, D, and F, which are 102mm, 188mm, and 270mm respectively; the standard mover outlet is equipped with L05 (0.5m) option, the matching stator model is MMW060-L96, and the standardized mounting hole layout and compact size adapt to the equipment frame layout; the power and electrical parameters are accurately controllable, the continuous thrust ranges from 102N to 306N, and the corresponding peak thrust is 317N to 845N. Combined with optimized phase resistance, phase inductance and back EMF parameters, the electromagnetic conversion efficiency and operational stability are improved simultaneously.

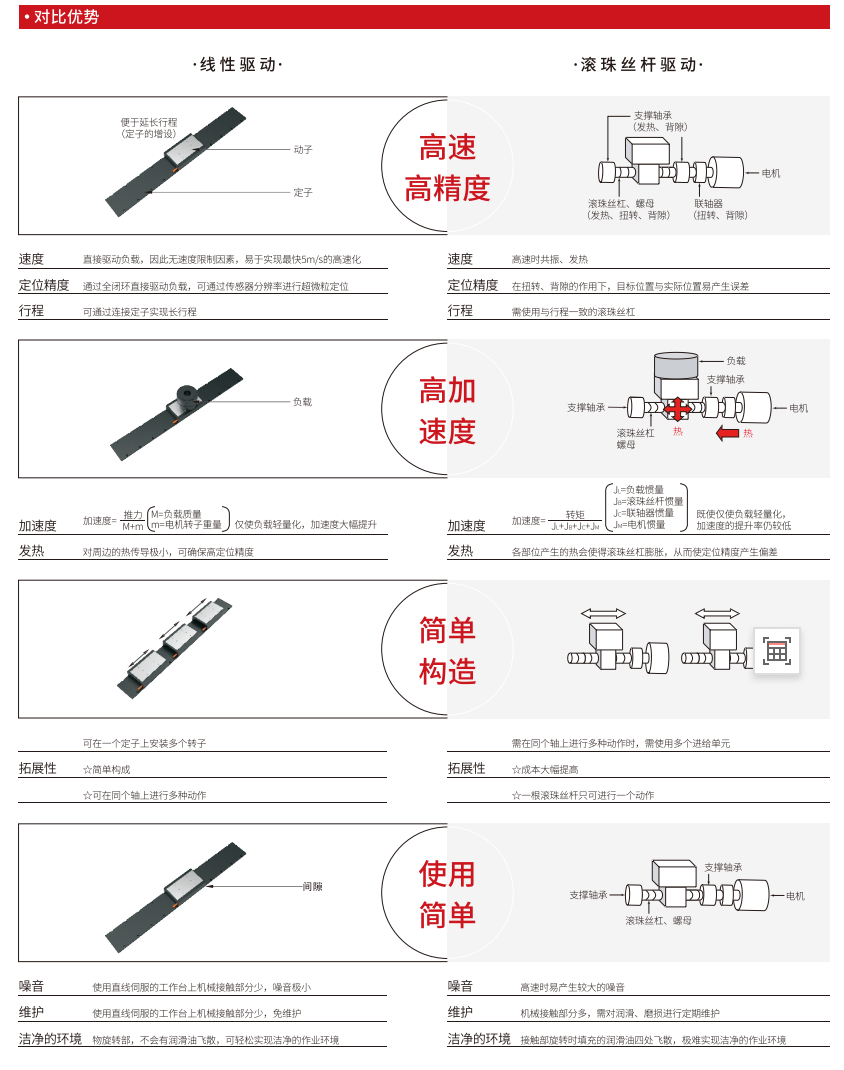

Relying on parameter advantages and core selling points, the CMW060 Series has achieved in-depth adaptation in medium-load precision scenarios such as 3C electronics, new energy, and laser processing:

In the field of medium-load handling in 3C electronics, the CMW060B, with its compact mover design and continuous thrust, can drive the transfer modules of components such as mobile phone middle frames and tablet casings to run at high speed. The low cogging force feature effectively offsets start-stop vibration, ensures the position accuracy of components during transfer, and adapts to mass production needs;

In the new energy battery manufacturing link, it can stably drive pole piece conveying and detection mechanisms, easily meeting the load needs of single or small stacked pole pieces. The high-rigidity structure brought by iron-core technology avoids transmission deformation and ensures the flatness of pole piece edges;

In laser processing scenarios, this series is combined with a high-precision grating encoder, which can drive laser cutting heads and welding heads to complete uniform feeding and precise positioning, adapting to small and medium-sized laser welding and precision cutting equipment. The combination of high acceleration and low cogging force simultaneously meets the process requirements of "high-speed processing and low heat-affected zone".

Based on mature iron-core technology, the CMW060 Series achieves a precise balance of performance in a compact body:

Low Cogging Force for More Stable Operation: Through optimized iron core tooth shape and winding distribution, thrust fluctuation is effectively reduced. Even during high-speed start-stop, it can maintain smooth movement, avoiding material deviation or equipment resonance.

High Acceleration Response: The compact structure combined with low inertia design can achieve faster acceleration and deceleration, greatly improving the production cycle of equipment, especially suitable for high-speed production line scenarios such as 3C electronics and food packaging.

Compact Size with Strong Adaptability: Under the body width of only 60mm, it can output stable continuous thrust without additional installation space, making the equipment layout more flexible.

En

En