DGSMARTWIN CFB035: An Industrial Powerhouse with Great Energy in a Small Size

In the field of industrial automation, linear motors, as the core components for achieving high-precision and high-speed linear motion, their performance directly determines the operating efficiency and precision of equipment. The CFB double-sided iron-core linear motors launched by dgsmartwin have broken the dilemma of traditional linear motors that "thrust and stability cannot be achieved at the same time". As the benchmark model of this family, the CFB035, with its core characteristics of "small size, high thrust, and high precision", has become a powerful partner for high-end industrial equipment. After years of deep involvement in the industrial transmission field, it is not difficult to find that an excellent linear motor must be both "powerful" and "precise". The CFB035 series precisely meets this core demand, perfectly interpreting the product logic of "small size solving big needs" with flexible dimensions and strong performance.

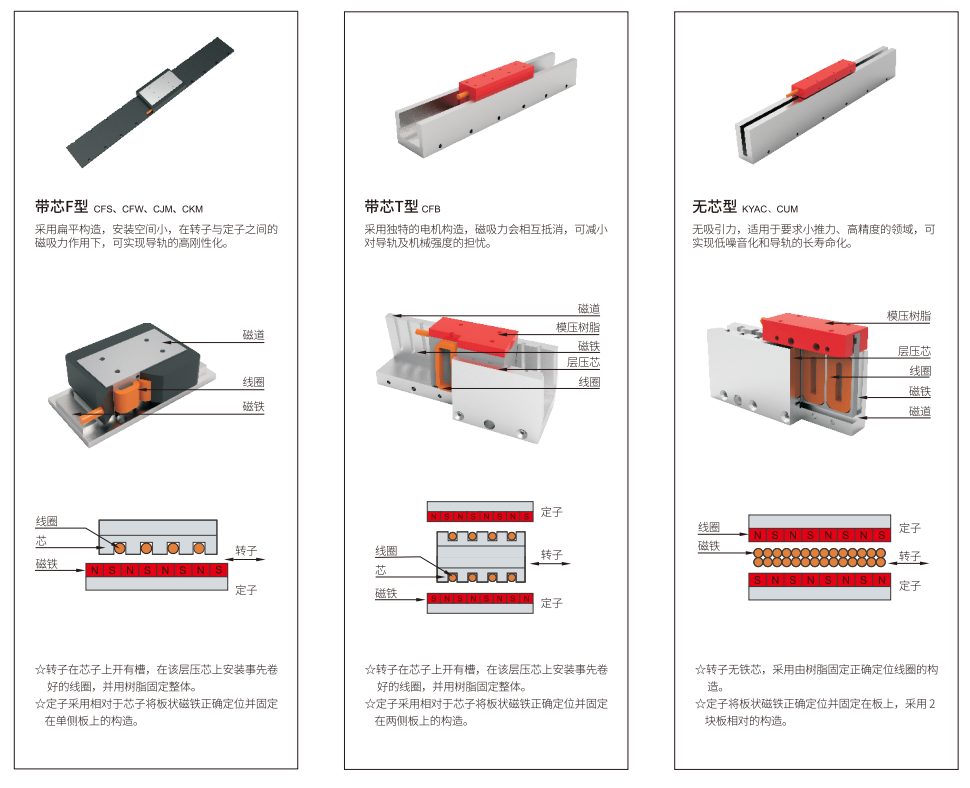

From the perspective of core parameters, the flexibility and explosive power of the CFB035 can be called an industry benchmark. The mover size design is highly adaptable, with a width of 35mm and a length extending from 80mm to 274.4mm. It can be flexibly selected according to the equipment installation space without major modifications to the equipment structure, adapting to various small and medium-sized precision equipment. The thrust performance is even more impressive: the continuous thrust ranges from 41N to 162N, and the peak thrust ranges from 110N to 438N, with a thrust density far exceeding that of similar products. The core secret of all this lies in its innovative double-row iron core shaping structure — optimized on the basis of iron-core technology, adopting a double-row iron core parallel layout. It not only retains the high thrust advantage of iron-core motors, but also cleverly offsets the cogging force of traditional iron-core motors, combining the dual characteristics of high thrust of iron-core motors and zero cogging force of coreless motors. During operation, the speed fluctuation is lower, the following error is smaller, and the stability is far superior to similar products. Combined with a high-precision encoder, it can achieve micron-level positioning, fully meeting the needs of precision operations.

The value of this motor can only be fully reflected when it is applied to actual scenarios. Its application scope covers many high-end manufacturing fields such as new energy, 3C electronics, and laser processing:

In the new energy lithium battery pole piece buffering scenario: relying on the stable power output brought by the double-sided iron-core structure, combined with the characteristic of no vertical suction, it ensures that there is no jitter or deviation during the pole piece conveying process, avoids pole piece wrinkling or damage, and guarantees the yield of subsequent lamination and cutting processes. Its characteristics of high thrust and high acceleration perfectly meet the core demand of "fast and stable" in lithium battery production lines.

In the field of AOI optical inspection: the high-speed response and micron-level precise positioning capabilities are prominent, which can drive the inspection lens to scan quickly and greatly improve inspection efficiency. At the same time, the extremely low speed fluctuation ensures inspection precision, perfectly adapting to the micron-level defect inspection needs of semiconductors and 3C products.

In laser cutting and precision welding scenarios: its precise trajectory control capability can keep the laser focus or welding torch always aligned with the predetermined path, effectively avoiding overburning, burrs or weld deviation, and improving processing quality. The high rigidity of the motor ensures stability during high-speed processing, and even in a narrow equipment space, it can be easily installed with its compact size.

With its core advantages of "stability, speed, and precision", the CFB035 series linear motor shines in various precision operation scenarios, proving with strength that a small size can carry big needs and becoming a well-deserved industrial powerhouse.

En

En