DGSMARTWIN KYAC4000 Series: Empowering the Upgrade of Medium-Light Load Precision Scenarios

In the field of medium-light load precision direct drive, the core value of coreless motors lies in balancing "high-speed response" and "operation smoothness". The dgsmartwin KYAC4000 Series coreless linear motors, based on this pain point, have become the preferred power solution in the field of high-end precision manufacturing by virtue of refined parameter calibration and differentiated technical design.

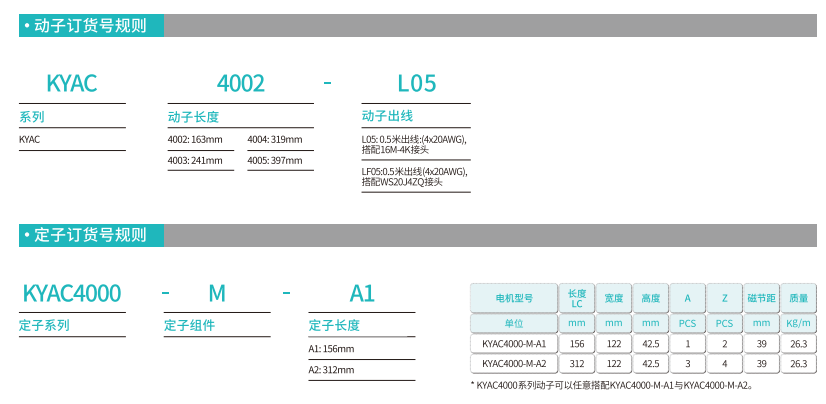

As a large-scale power model in dgsmartwin's coreless linear motor matrix, the series has clear parameter gradients and fits actual working conditions: the mover length covers multiple gradients from 4002 (163mm) to 4005 (397mm), the continuous thrust smoothly transitions from 195.2N to 488.0N, and the peak thrust can reach up to 2287.5N, perfectly adapting to the scenario needs of transition from medium-light load to medium load; the stator is matched with two specifications: A1 (156mm) and A2 (312mm), with a magnetic pitch of 39mm, which can be flexibly combined according to stroke requirements; the standard mover outlet is equipped with L05 (0.5m) option, taking into account integration convenience.

Relying on core technologies and precise parameters, the KYAC4000 Series has achieved in-depth implementation in diverse high-end precision scenarios, and every selling point accurately matches industry pain points:

In the 3C electronic screen lamination and assembly scenarios: With the development of 3C products towards thinness, lightness and flexibility, the lamination and assembly of screens and chips have extremely high requirements for motion smoothness and precision. Traditional motors may produce slight vibration and speed fluctuation due to cogging effect during operation, leading to jitter and deviation of flexible screens during transportation and lamination, which in turn causes screen breakage or misalignment and affects product yield. However, the KYAC4000 Series achieves ultra-smooth motion by virtue of the zero cogging effect brought by coreless technology, and its speed fluctuation is controlled at the micron level, ensuring no jitter or deviation when transporting and laminating flexible screens and precision chips, effectively avoiding the risk of breakage or misalignment, and providing a solid guarantee for improving product yield. In addition, under the trend of intelligent production, the high-speed response capability of the motor can quickly cooperate with the intelligent control system to achieve efficient and precise automatic lamination and assembly.

In the field of AOI optical inspection: With the continuous progress of 3C product and semiconductor manufacturing processes, the precision requirements for product defect detection are getting higher and higher, requiring detection of micron-level or even smaller defects. At the same time, in order to improve production efficiency, the inspection lens needs to scan the product surface quickly and stably. Traditional motors may cause missed detection or false detection during the inspection process due to speed fluctuation and inaccurate positioning. The high-speed response and micron-level precise positioning capabilities of the KYAC4000 Series are fully exerted, which can drive the inspection lens to scan quickly and stably. Its almost zero speed fluctuation ensures the detection precision of micron-level defects in semiconductors and 3C products, perfectly adapting to the quality control needs of high-end manufacturing.

Under the trend of green manufacturing, the efficient operation of the motor can reduce energy consumption and carbon emissions during the inspection process.

In the scenarios of precision laser marking and micro-part welding: In high-end manufacturing fields such as aerospace and medical devices, the requirements for fine processing of products are extremely high. Laser marking and micro-part welding require the laser focus or welding torch to always accurately fit the complex predetermined path. Any slight deviation may lead to overburning, burrs or weld deviation, affecting product quality and performance. Moreover, these fields have high requirements for equipment space utilization, requiring complex processing tasks to be completed in a narrow space. The excellent dynamic curve motion capability of the KYAC4000 Series can make the laser focus or welding torch always accurately fit the complex predetermined path, effectively avoiding overburning, burrs or weld deviation, and significantly improving the quality of fine processing. Even in a narrow equipment space, it can be easily installed with its compact size. At the same time, its lightweight design meets the weight reduction needs of equipment in fields such as aerospace, helping to improve the overall performance of products.

With the in-depth advancement of the "Made in China 2025" strategy, core components such as the KYAC4000 will be applied in more key fields. It is not only a high-performance linear motor, but also an important force driving the transformation of China's manufacturing industry towards high-end and intelligence, interpreting the industry value of "small size carrying big needs" with practical actions.

En

En