DGSMARTWIN BMW200 Series: Empowering Medium-High Load and Long Stroke Precision Drive

In medium-high load and long stroke automation scenarios, dust and chip intrusion, as well as long-stroke precision attenuation, are two core pain points plaguing engineers. The dgsmartwin BMW200 Series enclosed linear motor module accurately addresses this industry demand, and has become the preferred solution in complex industrial environments with its threefold advantages of "protection, precision, and power".

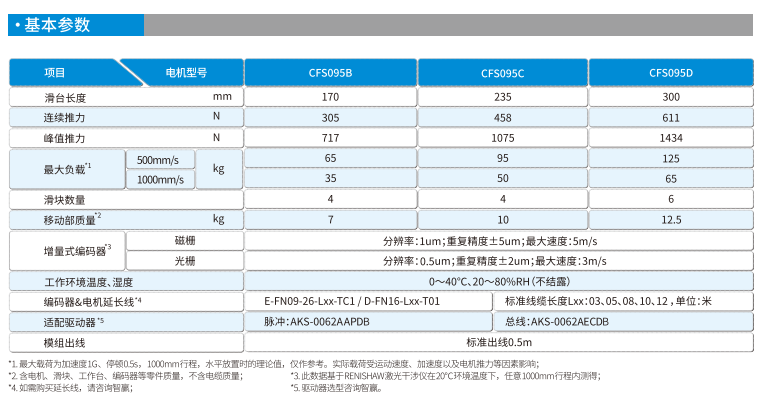

As the core model of dgsmartwin's medium-high load modules, the BMW200 Series has parameter gradients that fit actual working conditions. Its standard maximum effective stroke can reach 4000mm, which can be flexibly adapted according to equipment needs. The continuous thrust ranges from 305N to 611N, and the corresponding peak thrust is 717N to 1434N. It is matched with the CFS095 Series linear motor: the CFS095B slide table has a length of 170mm and a maximum load of 65kg; the CFS095D slide table has a length of 300mm and a load increased to 125kg.

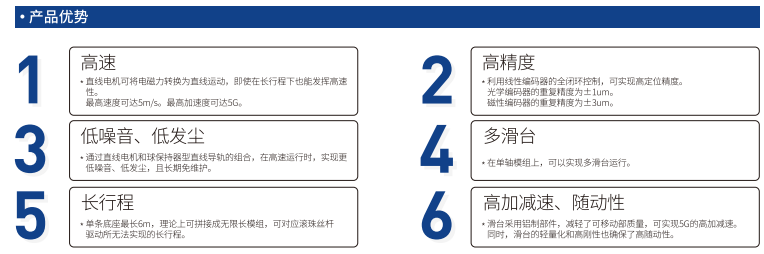

The fully enclosed structure of the BMW200 Series is a major highlight. It can not only effectively isolate dust and debris in the production environment, protect key components such as internal guide rails from wear, but also greatly reduce the generation of dust, making it particularly suitable for lithium battery and semiconductor workshops with extremely high cleanliness requirements.

The high-rigidity guide rail built into the module ensures stability under high-speed and heavy-load operation. The linear motor itself has no mechanical contact, avoiding wear, clearance and other problems that may occur in traditional lead screw transmission. Combined with micron-level positioning accuracy, it achieves the perfect unity of "long stroke" and "high precision".

Relying on hard-core parameters and differentiated selling points, the BMW200 Series has achieved in-depth application in medium-high load and long stroke scenarios in multiple industries, and every design is closely aligned with actual production needs:

Medium-Load Handling Field in 3C Electronics

In the medium-load handling scenario of 3C electronics, the long-stroke advantage of the BMW200 Series can perfectly adapt to the cross-station material transfer of large-scale assembly lines. Its enclosed structure can effectively isolate dust and debris generated during production, avoiding wear of guide rails and other components. The 305N-level continuous thrust can stably drive heavy-load tooling such as mobile phone middle frames and laptop casings. Equipped with a high-speed movement capability of up to 5m/s, it can still maintain micron-level positioning accuracy under high-frequency start-stop, perfectly adapting to the mass production rhythm. At the same time, low-noise operation optimizes the workshop working environment.

New Energy Battery Module Assembly Scenario

In the new energy battery module assembly scenario, the 4000mm long stroke can meet the long-distance transportation needs of battery modules. The 611N continuous thrust can easily cope with the heavy-load drive after module stacking. The enclosed protection can block the intrusion of pole piece debris, and the low dust generation characteristic also effectively avoids pollution to battery materials. The high-rigidity guide rail avoids module deviation during transportation, ensures the consistency of subsequent assembly, and lays a solid foundation for the efficient operation of lithium battery production lines.

Automated Inspection Production Line

In the automated inspection production line, the BMW200 Series can drive inspection tooling to complete long-stroke continuous inspection with its stable power output and precise positioning capability, adapting to the integration needs of various medium and large-sized equipment. The external centralized oil injection device simplifies maintenance and can effectively reduce the long-term operation cost of equipment.

As the benchmark model of dgsmartwin's medium-high load enclosed modules, the BMW200 Series not only balances medium-high load power output and long-stroke adaptability, but also breaks the application limitations in complex environments with enclosed protection. It has become a key power support for promoting equipment upgrading in 3C, new energy, automated inspection and other fields, and has won wide recognition from leading industry enterprises.

En

En