CKM030 Series Iron-Cored Linear Motors: A Technological Breakthrough for High-Precision and Heavy-Load Applications

In the tide of industrial automation upgrading toward high precision and heavy load, iron-cored linear motors have emerged as the core power components of high-end equipment, thanks to their unique technical advantages. The CKM030 series iron-cored linear motors independently developed by DG SMARTWIN INTELLIGENT EQUIPMENT CO., LTD. deeply integrate the essence of iron-cored technology. With ultra-low cogging force, high thrust density and high rigidity, they deliver an innovative driving solution for heavy-load and high-precision working conditions.

Iron-cored technology is the core competitiveness of the CKM030 series. Compared with ironless motors, this series adopts an optimized coupling design of iron core and coil, which greatly improves thrust output while maintaining high structural rigidity. It can effectively resist load impact and ensure operational stability. Its ultra-low cogging force design is a major highlight. Through the optimization of magnetic field distribution and improvement of cogging structure, thrust ripple is minimized, enabling the motor to maintain stable output even at low speeds and avoid positioning errors caused by the cogging effect in traditional motors. In addition, the motor adopts a high-efficiency heat dissipation structure with a thermal dissipation constant of 0.5-3W/℃. Combined with reasonable winding layout, it effectively controls temperature rise during continuous operation and ensures stable performance during long-term high-intensity work.

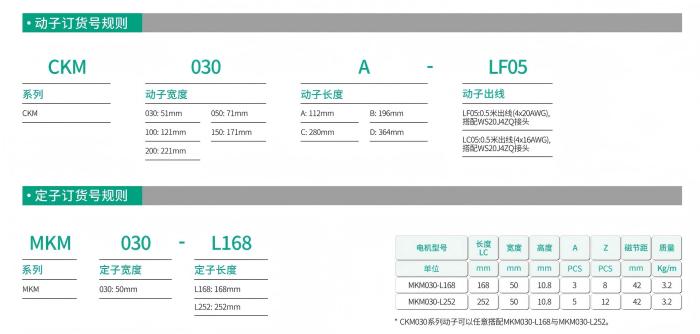

The comprehensive optimization of performance parameters lays the foundation for the CKM030 series to adapt to complex scenarios. The mover length covers four specifications: 112mm, 196mm, 280mm and 364mm, corresponding to a continuous thrust of 105N-421N and a peak thrust of 239N-948N, allowing flexible model selection according to different load requirements. In terms of electrical characteristics, the thrust constant ranges from 22.3N/A to 66.9N/A, and the back EMF constant ranges from 18.3V/(m/s) to 54.9V/(m/s). All indicators are balanced and excellent, ensuring precise and controllable power output. The stator width is standardized at 50mm for strong installation compatibility, and multiple options are available for mover lead-out modes to adapt to the spatial layout requirements of different equipment.

The CKM030 series is precisely applicable to the core fields of high-end manufacturing. In the 3C electronics industry, it can be used in precision placement and testing equipment. With its high positioning accuracy and stable operation performance, it improves the qualified rate of product assembly. In new energy battery production, it is suitable for processes such as pole piece cutting and lamination, where its high thrust and low ripple characteristics ensure processing precision and efficiency. In laser processing equipment, its fast response capability and precise trajectory control help achieve high-precision cutting of complex workpieces. In addition, in scenarios such as heavy-duty positioning platforms and automated testing lines, this series of motors can also improve the overall operational performance of equipment by virtue of their high rigidity and low loss advantages.

En

En