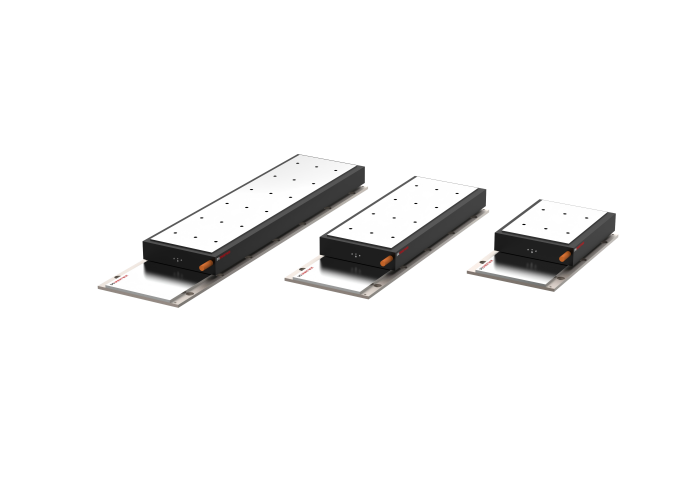

CFW135 Series Iron-Cored Linear Motors: Technical Essentials and Scenario Applications

In the field of precision transmission and positioning technology, linear motors are increasingly emerging as the core components of automated equipment and systems, thanks to their direct-drive mechanism, high precision, and high-speed performance. Among these, the CFW135 series iron-cored linear motors stand out prominently among numerous linear motor products by virtue of their unique technical advantages and broad application adaptability. This paper provides an in-depth technical analysis of the features, advantages, parameters, and application scenarios of the CFW135 series iron-cored linear motors.

Iron-Cored Design: The Cornerstone of Power and Stability

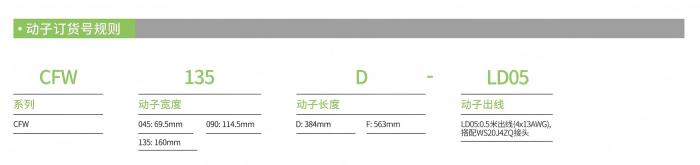

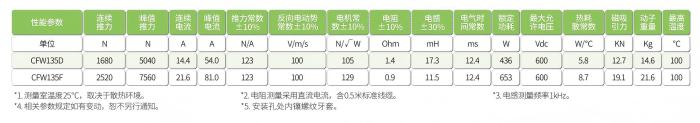

The CFW135 series linear motors adopt an iron-cored structure, which serves as the foundation for their superior performance. The integration of iron cores not only enhances the magnetic flux density of the motors, but also significantly boosts their continuous thrust and peak thrust. Specifically, the series offers flexible mover width and length dimensions to cover a wide range of thrust requirements. The continuous thrust ranges from 1680N to 2520N, and the peak thrust extends to a broad interval of 5040N to 7560N, fully meeting the needs of applications demanding heavy loads and high dynamic response.

The iron-cored design also brings additional benefits of low cogging effect and low speed fluctuation. Cogging effect is a common force fluctuation phenomenon during linear motor operation, which impairs motion stability. Through sophisticated magnetic circuit design and optimization, the CFW135 series effectively suppresses cogging force, ensuring high precision and stability of the motors even during high-speed movement. Meanwhile, the low speed fluctuation characteristic enables the motors to maintain smooth operation at high speeds, which is crucial for precision machining and testing processes.

2. Technical Advantages: High Efficiency, Precision, and Reliability

In terms of parameters, the CFW135 series not only provides a wide range of size options, but also achieves dimensional compatibility with imported brands from overseas, with equivalent performance. Moreover, it features more controllable delivery lead times and more favorable costs, offering users a cost-effective solution.

3. Performance Parameters and Technical Details

In terms of technical parameters, the CFW135 series linear motors demonstrate its strength as a high-end transmission component. Its positioning accuracy of ±2μm and repeat positioning accuracy of ±1μm ensure precise applications in fields such as semiconductor inspection and precision machining. In addition, the motor features a compact structure and strong adaptability, facilitating easy integration into various types of automated equipment.

4. Application Scenarios: The Driving Force for Precision Manufacturing

The CFW135 series linear motors boast extremely broad application scenarios, particularly in the fields of semiconductor Automated Optical Inspection (AOI) and laser processing. In semiconductor AOI inspection, the high-speed and high-precision characteristics of the motors ensure that inspection equipment can quickly and accurately capture tiny defects on the chip surface, improving product yield. In laser cutting and chamfering applications, the precise control and stability of the motors guarantee smooth and accurate machining edges, satisfying the requirements of high-end manufacturing.

Specific application cases include AOI inspection equipment adopting a linear motor XY + DD motor R-axis structure to achieve high-precision positioning at high speeds; laser cutting platforms utilizing a marble base and XYY structure combined with interpolation linkage control to achieve micron-level machining accuracy.

En

En