SMARTWIN KYAC4000 Series: Empowering Upgrades in Medium-Light Load Precision Applications

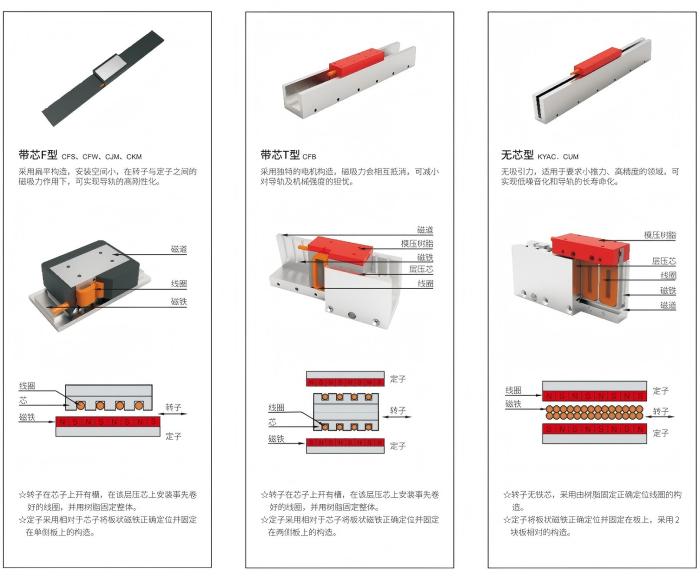

In the field of medium-light load precision direct drive, the core value of ironless linear motors lies in balancing high-speed response and smooth operation. The SMARTWIN KYAC4000 series ironless linear motor is developed precisely to address this demand. With refined parameter tuning and differentiated technical design, it has become a preferred power solution for high-end precision manufacturing.

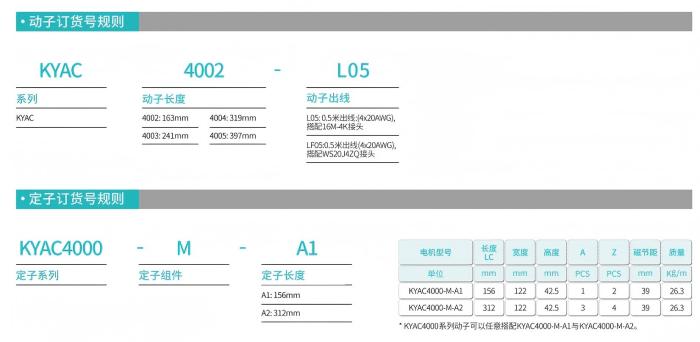

As a large-size model in SMARTWIN’s ironless linear motor portfolio, this series features a well-defined parameter range tailored to real working conditions. The forcer length is available in multiple grades from 4002 (163 mm) to 4005 (397 mm). Continuous thrust ranges smoothly from 195.2 N to 488.0 N, with a peak thrust of up to 2287.5 N, making it perfectly suitable for applications transitioning from medium-light load to medium load. The stator is supplied in two specifications: A1 (156 mm) and A2 (312 mm), with a magnetic pole pitch of 39 mm, supporting flexible combination according to stroke requirements. The standard forcer cable outlet is configured with L05 (0.5 m), ensuring convenient integration.

In 3C Electronic Screen Bonding and Assembly

As 3C products evolve toward slimmer, lighter and flexible designs, the bonding and assembly of screens and chips impose extremely high requirements for motion smoothness and precision.

Traditional motors may generate minor vibrations and speed fluctuations due to cogging effects, causing jitter and misalignment during the conveying and bonding of flexible screens, which can lead to screen cracking, poor alignment and reduced yield.

In contrast, the KYAC4000 series achieves ultra-smooth motion thanks to the zero cogging effect brought by ironless technology, with speed fluctuation controlled at the micron level. This ensures jitter-free and offset-free conveying and bonding of flexible screens and precision chips, effectively eliminating the risks of cracking and misalignment, and providing solid support for improving product yield.

Furthermore, driven by the trend of intelligent manufacturing, the motor’s high-speed response enables rapid coordination with intelligent control systems, realizing efficient and precise automated bonding and assembly.

In AOI Optical Inspection

In line with the trend of green manufacturing, the motor’s high-efficiency operation reduces energy consumption and lowers carbon emissions during the inspection process.

In Precision Laser Marking and Micro-Part Welding

High-end manufacturing sectors such as aerospace and medical devices impose stringent requirements on fine machining. Laser marking and micro-part welding demand that the laser focus or welding torch accurately follows complex predefined paths at all times. Any slight deviation can result in overburning, burrs or weld offset, impairing product quality and performance.

In addition, these sectors have high demands on equipment space utilization, requiring complex machining tasks to be completed in confined spaces.

The exceptional dynamic contouring capability of the KYAC4000 series keeps the laser focus or welding torch precisely aligned with complex predefined paths, effectively avoiding overburning, burrs and weld deviation, and significantly improving the quality of fine machining.

En

En