SMARTWIN CUM5 Series: Medium-Load Ironless Direct Drive, Unlocking New Possibilities in Precision Applications

In the field of medium-load precision direct drive, the selection of ironless linear motors often faces a dilemma between “insufficient thrust” and “unsmooth operation”. Traditional motors either fail to meet medium-load application requirements due to limited thrust, or generate vibration caused by cogging effects during operation, which compromises machining precision.

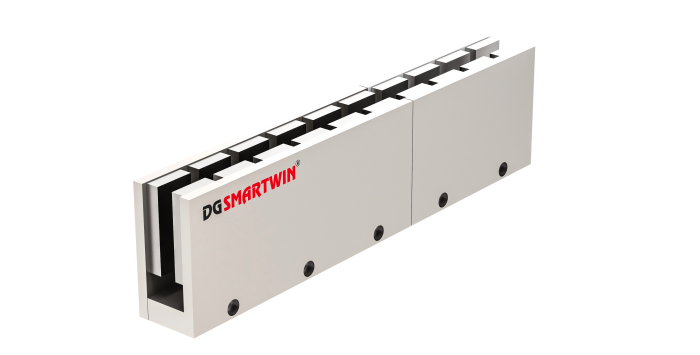

The SMARTWIN CUM5 series ironless linear motor breaks precisely through this industry bottleneck. Featuring a compact design with a forcer width of 38.3 mm, it is engineered to provide high-dynamic, high-precision vertical motion axes for equipment, while simplifying mechanical structures, making it the preferred solution for medium-load scenarios.

As the core medium-load model in SMARTWIN’s ironless motor portfolio, this series offers two main forcer length options: 121 mm and 241 mm. The corresponding continuous thrust ranges from 119.8 N to 239.5 N, with peak thrust spanning 676.9 N to 1353.7 N, covering full power demands for medium-load operations. Multiple stator specifications are available, including L120 (119.7 mm) and L180 (179.5 mm), supporting flexible configuration according to equipment stroke requirements.

The forcer comes standard with an L05 (0.5 m) cable and parallel wiring design, balancing ease of integration and electrical stability.

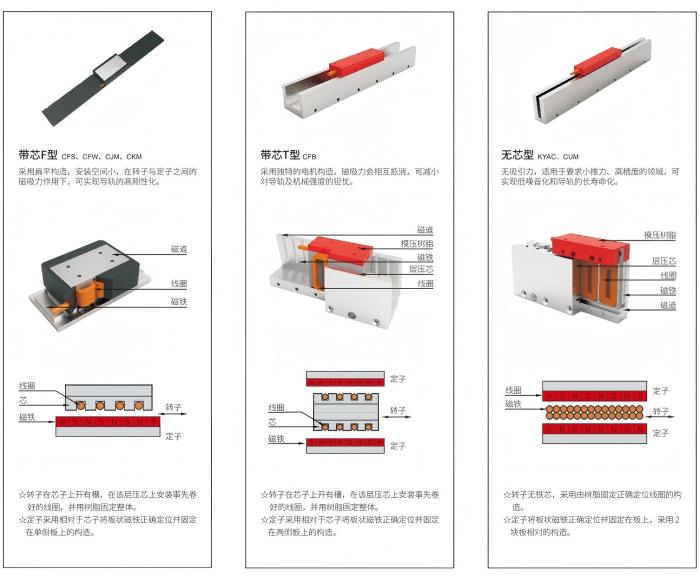

Its core advantages stem from deeply optimized ironless technology. The ironless structure completely eliminates the cogging effect and vertical magnetic attraction inherent in traditional iron-core motors.

Cogging effect causes speed ripple and vibration during operation, impairing motion smoothness and positioning accuracy. Vertical magnetic attraction increases the complexity and cost of vertical axis installation, requiring additional brake mechanisms for operational safety.

In contrast, the SMARTWIN CUM5 series ironless linear motor achieves zero-vibration smooth operation and eliminates the need for extra brake structures in vertical axis installations.

In addition, its hollow coil design significantly reduces eddy current loss, simultaneously improving heat dissipation efficiency and dynamic response performance. With CE certification and environmental compliance, it fully meets the requirements of international precision manufacturing.

Backed by core technologies and well-tuned parameters, the CUM5 series has been widely deployed in diverse medium-load precision scenarios, with every design detail precisely matching real industry demands.

- In medium-load handling for 3C electronicsThe CUM5B model, with its compact 121 mm forcer length and 119.8 N continuous thrust, is ideal for heavy-duty transfer modules of components such as mobile phone middle frames and laptop housings.Thanks to the zero cogging effect of the ironless structure and low inertia characteristics, it effectively suppresses vibration during high-speed start-stop cycles. During high-speed conveying, components remain free from scratches caused by vibration and positional deviation, perfectly matching mass production rhythms and greatly improving production efficiency and product quality.

- In semiconductor inspection applicationsSemiconductor inspection imposes extremely high precision requirements, where even minor vibration or positioning error can damage delicate chips.With low inertia and high dynamic response, the CUM5 series ironless linear motor drives inspection stages to perform high-speed scanning of small wafers. Meanwhile, the smooth thrust output of the ironless motor limits positioning error to the micron level, avoiding damage to precision chips caused by vibration and unstable thrust common in traditional motors, thus ensuring the accuracy and reliability of semiconductor inspection.

- In medical equipmentMedical equipment demands strict operational stability, cleanliness, and in some cases, complex trajectory control.The CUM5 series ironless linear motor features zero magnetic attraction, generating no electromagnetic interference to surrounding medical devices. Its clean, low-contamination operation makes it perfectly suitable for driving core components such as minimally invasive instruments and drug delivery pumps.

- Its outstanding dynamic contouring capability enables complex, smooth trajectory control, fulfilling the precise operation requirements of medical equipment. Furthermore, the compact size of this series allows easy integration inside equipment, saving installation space and enhancing overall system integration.

En

En