SMARTWIN BMW200 Series: Empowering Medium-High Load, Long-Stroke Precision Drive

In medium-high load, long-stroke automation scenarios, dust and chip intrusion, as well as precision attenuation over long strokes, are the two core pain points plaguing engineers. The SMARTWIN BMW200 series enclosed linear motor module targets these industry challenges precisely. With three core strengths — protection, precision and power — it has become the preferred solution for complex industrial environments.

The fully enclosed structure of the BMW200 series is a major highlight. It effectively isolates dust and chips from the production environment, protects key internal components such as guide rails from abrasion, and significantly reduces dust generation. This makes it especially suitable for lithium battery and semiconductor workshops with extremely high cleanliness requirements.

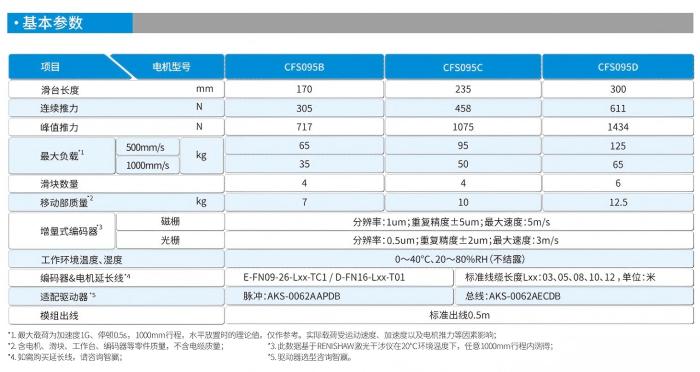

Equipped with high-rigidity guide rails built into the module, stability is guaranteed even under high-speed and heavy-load operation. As the linear motor features no mechanical contact, it eliminates issues such as wear and backlash common in traditional screw drive systems. Combined with micron-level positioning accuracy, it achieves a perfect integration of long stroke and high precision.

Medium-Load Handling in 3C Electronics

In medium-load handling for 3C electronics, the long-stroke advantage of the BMW200 series perfectly fits cross-station material transfer on large-scale assembly lines. Its enclosed structure reliably isolates dust and debris generated during production, preventing wear on guide rails and related components.

The 305 N-level continuous thrust stably drives heavy-duty fixtures such as mobile phone middle frames and laptop housings. With a maximum speed of up to 5 m/s, it maintains micron-level positioning accuracy even under high-frequency start-stop cycles, ideally matching mass production rhythms. Meanwhile, low-noise operation improves the overall workshop working environment.

New Energy Battery Module Assembly

The fully enclosed design blocks intrusion of electrode chips and debris, while its low-dust generation effectively prevents contamination of battery materials. High-rigidity guide rails eliminate module shifting during conveyance, ensuring consistency in subsequent assembly and laying a solid foundation for efficient operation of lithium battery production lines.

Automated Inspection Production Lines

In automated inspection lines, the BMW200 series delivers smooth power output and precise positioning, enabling inspection fixtures to perform long-stroke continuous inspection and adapting to the integration needs of various medium and large-scale equipment.

The external centralized lubrication device simplifies maintenance and effectively reduces the long-term operating cost of equipment.

En

En