DGSMARTWIN CUM2 Series: A Model of Coreless Direct Drive for Medium-Light Load and High-Dynamic Scenarios

In the field of industrial automation, every technological breakthrough drives a dual leap in production efficiency and precision. The CUM2 Series coreless linear motors launched by dgsmartwin have brought a new motion solution to scenarios such as high-end equipment manufacturing and precision inspection, relying on their innovative coreless technology.

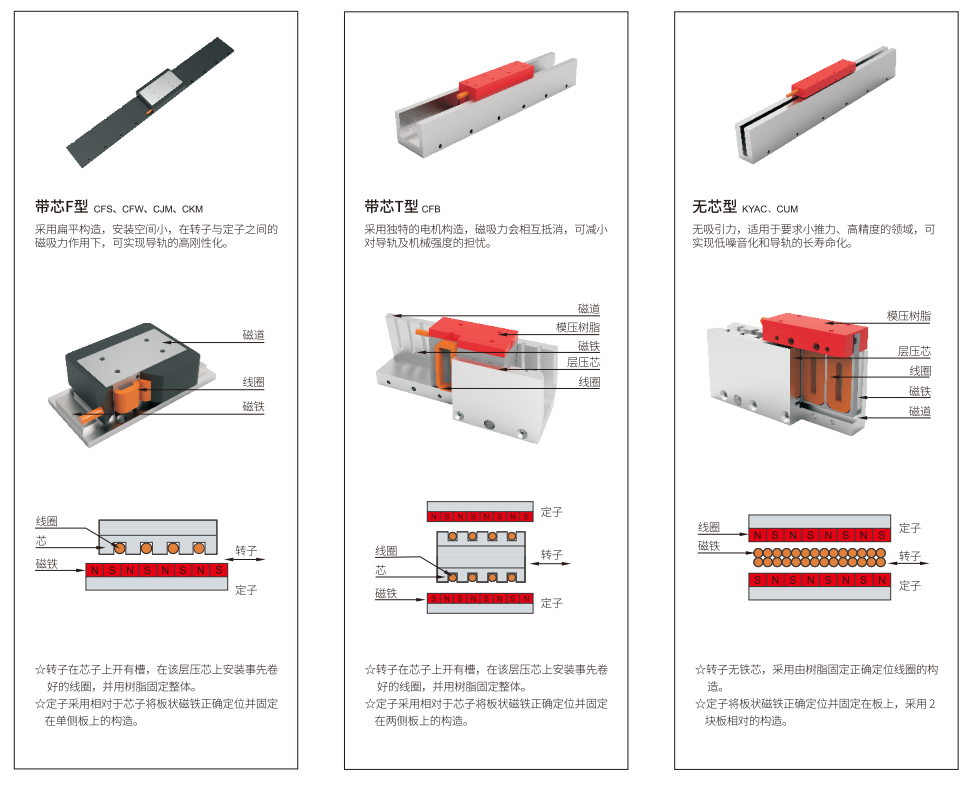

The core highlight of the CUM2 Series lies in its coreless technology, which fundamentally eliminates the cogging effect of traditional iron-core motors. This design brings three significant advantages:

Zero Cogging Force, Ultra-Smooth Motion: Avoids thrust fluctuation caused by cogging effect, with excellent dynamic curve motion performance, which can meet scenarios with extremely high requirements for motion smoothness such as laser processing and chip inspection.

Compact and Lightweight, Suitable for Vertical Scenarios: Small in size and light in weight, especially suitable for vertical axis installation scenarios. While reducing the load, it also makes the equipment structure design more flexible.

High Dynamic Response, Precise Position Control: The coreless structure brings lower inertia, enabling the motor to achieve faster acceleration and deceleration. Combined with a high-precision feedback system, the positioning accuracy can reach the micron level.

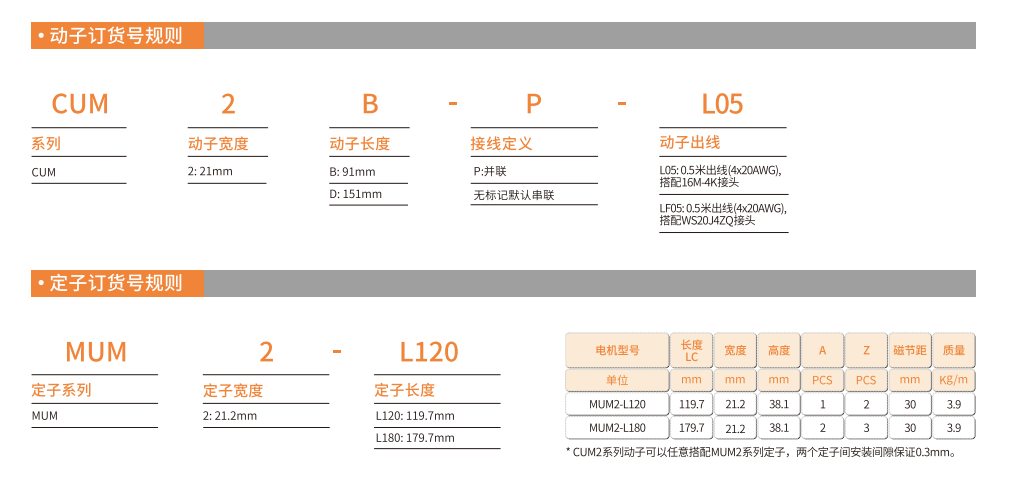

The parameters of this series have clear gradients and professional adaptation, with comprehensive coverage of core specifications: in terms of structure, the mover width is 21mm, the length ranges from 91mm to 151mm, the matching stator model format is MUM2-L120, and the standard mover outlet is equipped with L05 (0.5m) option, adapting to compact equipment layout; in terms of power performance, the thrust coverage gradient is clear: CUM2B has a continuous thrust of 25.5N and a peak thrust of 127.6N, while CUM2D has a continuous thrust of 51N and a peak thrust of 255.2N. The core selling points focus on the advantages of coreless technology, completely eliminating cogging effect and vertical magnetic attraction, simplifying vertical axis installation (no additional brake required). The hollow coil structure of the mover has excellent heat dissipation efficiency, balancing operational stability and international compliance requirements.

Relying on parameter advantages and core selling points, the CUM2 Series has achieved value implementation in diverse medium-light load precision scenarios, adapting to high-demand working conditions:

In the field of 3C electronic precision assembly, the compact mover volume and optional short mover length can be easily embedded in micro mounters and connector assembly equipment. High acceleration supports high-speed picking and placing of components, and the zero cogging force feature effectively eliminates operational jitter, greatly improving assembly yield.

In semiconductor inspection scenarios, this series is combined with dgsmartwin's self-developed driver and high-precision encoder to form a technical closed loop of "core components - control algorithms - precision feedback". The low thrust fluctuation and high dynamic response capability can meet the strict requirements of inspection equipment for positioning accuracy and speed.

In the field of medical equipment, its characteristics of no vertical magnetic attraction and zero cogging vibration, combined with smooth thrust output, can precisely control liquid flow rate. The compact volume and clean operation performance can be easily embedded in various high-precision medical equipment.

In the special-shaped cutting link of laser processing, the CUM2 Series can cooperate with circular interpolation control, and its excellent dynamic curve motion capability realizes taper-free cutting, adapting to the precision processing needs of mobile phone panels and automotive panels.

Whether it is high-speed mounting in the 3C electronics industry or precision sample transmission in the industrial field, the dgsmartwin CUM2 Series coreless linear motors can, with their excellent performance, become the core power for equipment upgrading, helping enterprises gain acceleration in the track of intelligent manufacturing.

En

En