Benchmark Manufacturer of Semi-Closed Protection: In-Depth Recommendation of dgsmartwin LMS99 Series Motor Modules

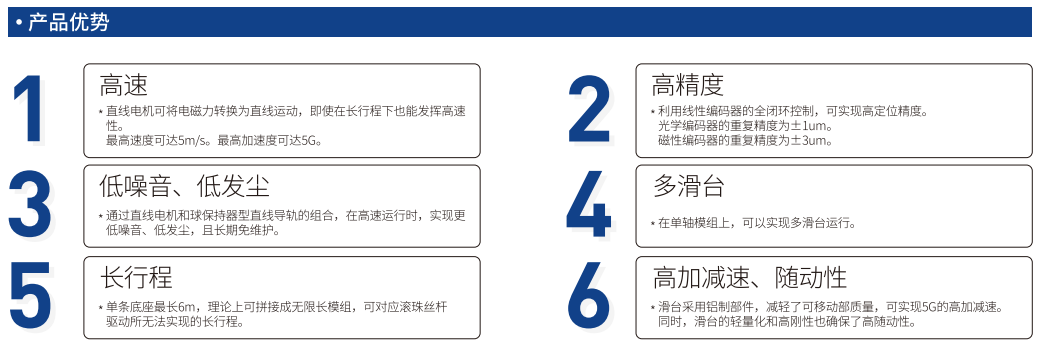

In the scenario of medium and long-stroke precision linear drive, the three core requirements of "high-speed stable operation, precise thrust output, and adaptation to complex working conditions" have become the key considerations for equipment selection. The dgsmartwin LMS99 Series semi-closed linear motor modules accurately break through the bottleneck, and have become the benchmark solution in this field with professional parameter calibration and core technical advantages.

The core parameters of this series cover the entire demand range of medium and long strokes, with precise and comprehensive technical specifications: in terms of power output, the continuous thrust accurately covers the gradient range of 48-193N, and the corresponding peak thrust is 113-452N, which can match the driving needs of different medium and light loads; in terms of operating performance, the maximum speed can reach 5m/s, the maximum stroke extends to 2890mm, and with a grating encoder of 0.5μm resolution, the repeat positioning accuracy is stably at ±2μm level, perfectly balancing high speed and high precision; in terms of structural parameters, it is equipped with high-precision guide rails, and the slide table length is divided into four grades according to sub-models: 110mm (CFS045A), 170mm (CFS045B), 235mm (CFS045C), and 300mm (CFS045D), adapting to the spatial layout of different equipment.

Relying on precise parameters and core selling points, the LMS99 Series has achieved precise value implementation in diverse medium and long-stroke scenarios.

In the field of 3C electronic manufacturing, the length of the slide table can flexibly adapt to PCB board dispensing and camera module mounting equipment; the high-speed feature can improve the mounting and dispensing beat, and the high positioning accuracy ensures the consistency of micro-component assembly;

In the new energy battery manufacturing link, the 2890mm long stroke is suitable for medium-distance transfer of battery cells and pole piece inspection lines; the high-rigidity design of the guide rail effectively offsets the vibration caused by high-speed start and stop; the 48-193N continuous thrust can stably drive the tooling platform; and the semi-closed protection is suitable for the dusty environment of the production line;

In the semiconductor auxiliary inspection scenario, the slide table length and low-speed fluctuation characteristics can support the inspection platform to complete the full-area scanning of small wafers, and the high-precision positioning ensures no omission of tiny defects.

In addition, in scenarios such as medium-distance workpiece handling and precision tooling positioning in automated production lines, its standardized mounting hole layout and multi-bus protocol compatibility can quickly connect to mainstream control systems, improving integration efficiency.

The core competitiveness of the LMS99 Series stems from its precise calibration in protection, speed, and thrust:

Semi-closed structure: While ensuring the heat dissipation efficiency of the equipment, it can effectively block the intrusion of large particles of dust and splashing droplets, adapting to most general industrial scenarios, without the need to install additional protective covers, reducing the overall equipment cost.

Industry-leading speed: The maximum speed can reach 5m/s, combined with the standard maximum stroke of 2890mm, which can greatly shorten the movement cycle of the equipment and significantly improve the production line beat.

Wide-range thrust output: The continuous thrust of the motor covers 48N-193N, which can flexibly adapt to various load requirements from light material handling to precision positioning, and can still maintain stable thrust output during long-stroke movement.

High-rigidity guide rail configuration: Adopting 15-2 guide rail specifications, matched with THK, HIWIN or dgsmartwin original guide rails, it can still maintain high precision and high rigidity under high-speed movement, avoiding positioning errors caused by vibration.

For equipment manufacturers pursuing "high stability, high precision, and high adaptability", the LMS99 Series is not only a power component with matched parameters, but also a key support for upgrading the core performance of equipment by virtue of its core selling points of semi-closed protection, high-speed and long-stroke, and flexible customization, demonstrating dgsmartwin's in-depth technical strength in the field of precision linear drive.

En

En