In modern industry, machines no longer simply move—they move intelligently, precisely, and predictably. Whether in CNC machining centers, robotic assembly lines, elevators, medical devices, or automated inspection systems, motion must be controlled with extreme accuracy and reliability. This is where motion control technology plays a critical role. At its core, motion control enables machines to execute controlled motion solutions that meet demanding requirements for speed, position, torque, synchronization, and repeatability. From simple linear positioning to complex multi-axis robotic motion control, motion control systems form the backbone of industrial automation.

This article provides a comprehensive overview of the motion control definition, explains how motion control systems work, explores essential motion control components, and highlights their applications across industries.

Motion Control Definition

To clearly understand modern automation, it is essential to begin with a precise motion control definition. Motion control refers to the technology and engineering discipline that governs how machines and mechanical systems move in a controlled, predictable, and repeatable manner. To define motion control accurately, it involves managing position, velocity, acceleration, torque, and synchronization using electronic and mechanical systems.

In industrial environments, motion control is no longer limited to simple start-and-stop movement. Instead, it has evolved into a sophisticated field combining electronic motion control, software algorithms, sensors, and real-time feedback. These systems enable machines to perform complex tasks such as contour machining, robotic assembly, synchronized lifting, and precision positioning.

Today's factories rely heavily on industrial motion control systems to achieve higher productivity, improved accuracy, and consistent product quality. Whether applied in CNC machining, robotics, elevators, or medical equipment, motion control technology ensures that movement is executed with precision and reliability.

At its core, motion control transforms electrical signals into mechanical action through controlled motion solutions. These solutions are not isolated components but complete systems designed to meet demanding industrial requirements.

Motion Control Basics and Motors

Understanding motion control basics starts with recognizing that motion is managed by a complete motion control system, not by a single device. A typical system consists of several interdependent elements working together in real time. A standard motion control system includes:

A motion controller

A motion controller driver (drive or amplifier)

Motors for motion control

Feedback devices such as encoders or sensors

Mechanical transmission components

The motion controller generates commands based on programmed logic. These commands are transmitted to the motion controller driver, which regulates voltage and current supplied to the motor. The motor produces movement, while a motion control sensor monitors actual position or speed and sends feedback to the controller. This closed-loop interaction forms the foundation of precision motion control. By continuously comparing commanded motion with actual motion, the system can correct errors instantly, ensuring high accuracy and repeatability.

In contrast, open-loop systems operate without feedback. While simpler and less expensive, open-loop solutions are limited in accuracy and are unsuitable for demanding industrial applications. As a result, most industrial motion control applications rely on closed-loop architectures.

Motion Control Components Functions

The performance of any motion control system depends on the quality and integration of its motion control components. Each component serves a specific function within the overall system.

Motion Controllers

Motion controllers act as the system's intelligence. They calculate trajectories, manage multi-axis synchronization, and execute control algorithms. Common types include:

Industrial motion controller

Programmable motion controller

Advanced motion controller

Servo motion controller

Stepper motion controller

Robot motion controller

A programmable motion controller allows engineers to define complex motion profiles, while an advanced motion controllersupports real-time analytics, diagnostics, and network communication.

Motors for Motion Control

Motors convert electrical energy into mechanical movement. Common motor types include servo motors, stepper motors, and direct-drive motors. Servo motors paired with a servo motion controller are widely used in CNC machines and robotics due to their high responsiveness and accuracy.

Motion Controller Driver and Drives

The motion controller driver regulates power delivery to the motor. It ensures smooth acceleration, precise torque control, and protection against overloads. In modern systems, drives often support ethernet motion control for fast, deterministic communication.

Sensors and Feedback Devices

A motion control sensor provides real-time feedback on position, speed, or acceleration. Encoders and linear scales are commonly used to support intelligent motion control, enabling error correction and performance optimization.

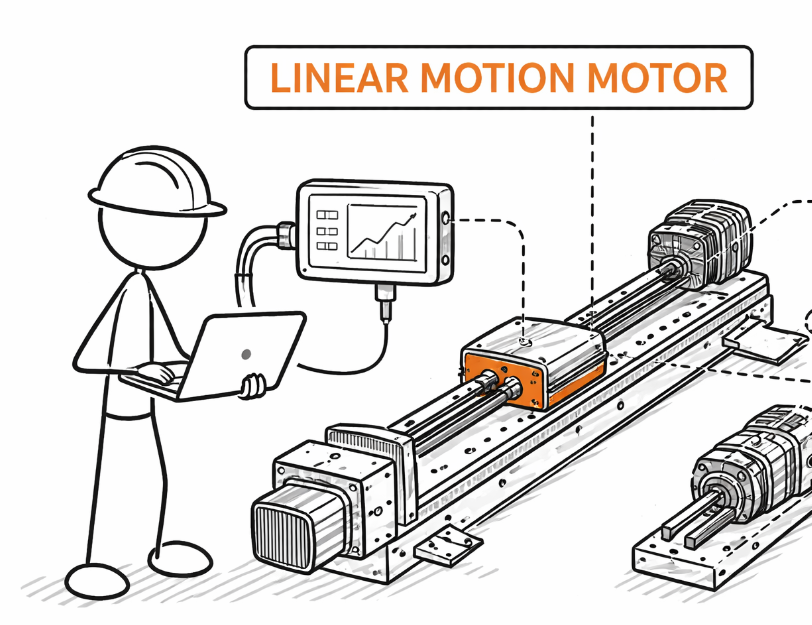

Linear Motion Control System

Linear motion control focuses on straight-line movement and is fundamental to many industrial applications. It is commonly used in CNC machining centers, automated inspection systems, semiconductor equipment, and medical devices. In linear systems, accuracy is critical. Any deviation directly affects product quality and system reliability. For this reason, linear motion control often relies on high-resolution feedback devices and rigid mechanical structures.

Applications of linear motion control include:

CNC axis positioning

Motion control slider mechanisms

Precision measurement platforms

Automated handling systems

By combining high-quality motors, controllers, and sensors, linear motion systems can achieve micron-level positioning accuracy. This level of performance is essential in medical motion control, where precision and safety are non-negotiable. Linear systems also play a key role in hybrid applications that combine linear and rotary motion, such as robotic arms or multi-axis machining centers.

Key Applications of Industrial Motion Control Systems

Modern industrial motion control systems are designed to operate continuously under demanding conditions. They must withstand vibration, temperature changes, electrical noise, and mechanical stress while maintaining consistent performance.

CNC Machining and Precision Manufacturing

In CNC machines, motion control determines tool path accuracy, surface finish, and repeatability. Servo-driven axes and closed-loop feedback systems are standard for achieving high-speed, high-precision machining.

Robotic Motion Control

Robotic motion control systems rely on a robot motion controllerto coordinate multiple joints simultaneously. These systems enable complex tasks such as welding, assembly, palletizing, and material handling.

Motion Controls Elevator Systems

In vertical transportation, motion controls elevator systems ensure smooth acceleration, precise floor leveling, and passenger safety. Motion control technology plays a direct role in ride comfort and energy efficiency.

Motion Control Camera and Imaging Systems

A motion control camera system synchronizes camera movement with machinery or subjects, enabling automated inspection and high-precision imaging in industrial and scientific environments.

Medical Motion Control

Medical equipment requires exceptional reliability. Motion control devices used in imaging systems, surgical robots, and diagnostic tools must meet strict regulatory standards while delivering smooth and accurate motion.

Motion Control as a Strategic Advantage

Motion control is no longer just a technical necessity—it is a strategic enabler of efficiency, quality, and competitiveness. From linear motion control in CNC machines to robotic motion control in smart factories and medical motion control in healthcare devices, motion control systems define how machines perform. By understanding motion control basics, components, theory, and applications, manufacturers can design better machines, reduce downtime, and achieve higher productivity. As automation advances, investing in robust, intelligent, and well-integrated industrial motion control systems will remain essential for future-ready operations.

En

En