Domestic Linear Motor Manufacturers - Smartwin Intelligent Equipment's Technological Breakthroughs and Industrial Value

Against the backdrop of accelerated localization of intelligent manufacturing and high-end equipment, linear motors, as core components of precision motion control, directly affect the accuracy, efficiency, and reliability of the entire equipment . Their technological breakthroughs and industrialization capabilities have become key to driving industry upgrades .

Domestic linear motor manufacturers with core technologies, complete solutions, and mature application experience are ushering in significant development opportunities. Dongguan Smartwin Intelligent Equipment Co., Ltd., with over a decade of technological accumulation and market cultivation, has become one of the most competitive manufacturers in the domestic direct drive field through a dual-drive model of "independent core component development + deep adaptation to industry scenarios. "

1. Self- sufficiency in Core Components

The core competitiveness of Smartwin Intelligent Equipment lies in its closed-loop technology capability covering the entire chain of "linear motor-driver-encoder", enabling upgrades from single products to precision control solutions.

The company not only provides stable and reliable linear motor bodies, but also independently develops matching servo drives and high-precision encoders. This end-to-end technology integration capability improves the dynamic response characteristics and positioning accuracy of the equipment, while effectively reducing the compatibility risks between components from multiple suppliers, providing customers with a more reliable system solution.

Smartwin Linear Motors : Targeting the needs of high precision and high speed, we have launched the CFS, CFW , CJM , CKM , and CMW series of linear motors, with thrust density reaching industry-leading levels, easily achieving high-speed operation of over 5m/s .

Smartwin Drives : In 2021, Smartwin launched its self-developed AKS series drives, supporting multiple encoder interfaces . Its high dynamic response control algorithm enables linear motors to accelerate more powerfully and respond faster.

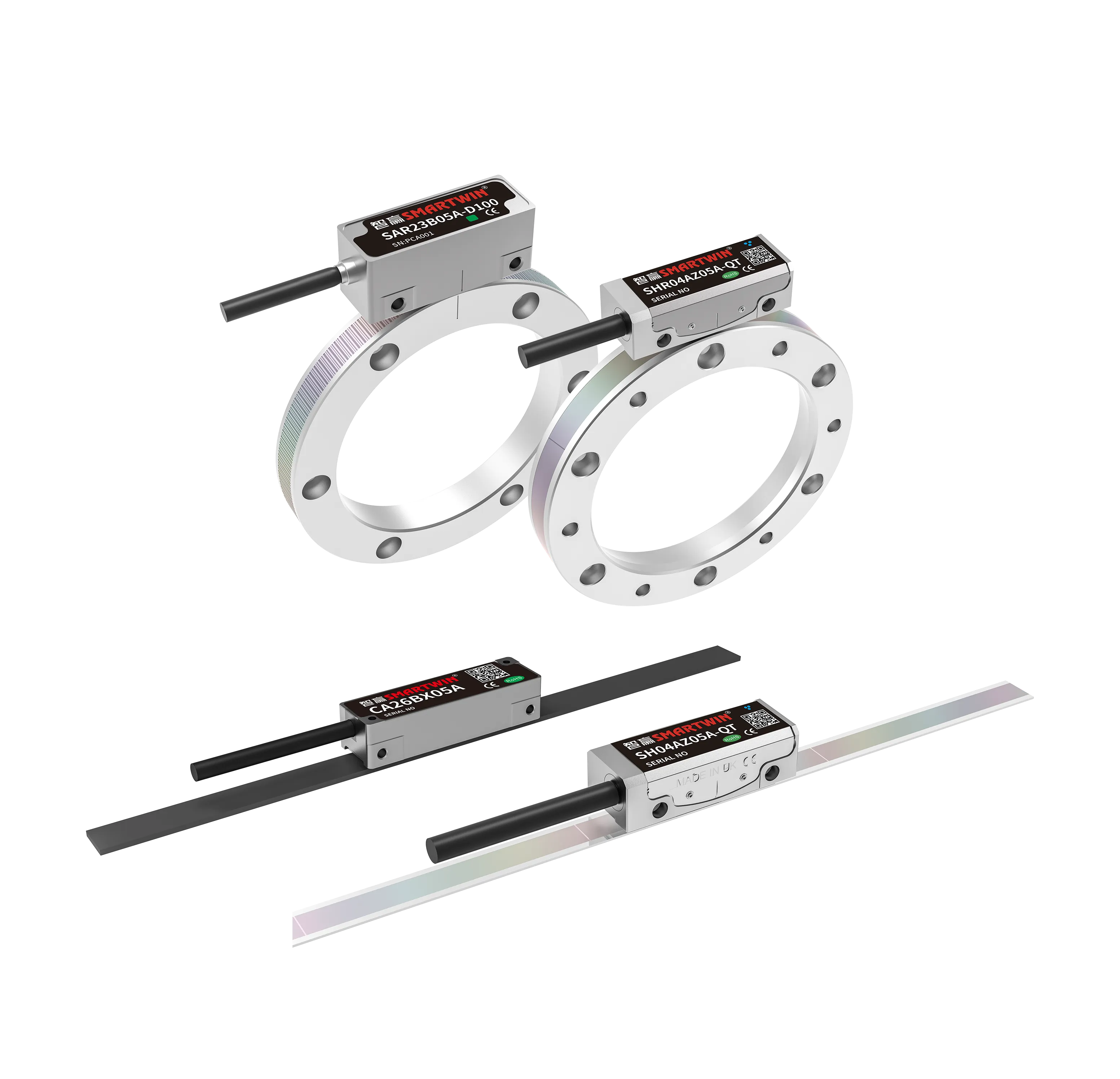

Smartwin Encoders: Smartwin's self-developed linear encoders (SH04/SA32 series), magnetic encoders (CH22/CA26 series), and circular encoders (SHR04/SAR23 series) support multiple signal transmission methods such as incremental ABZ signals, sincos signals, Biss-C signals, and Tamagawa signals, with a maximum resolution of 0.05μm.

2. Deeply Adapted to High-end Manufacturing Scenarios

needs to be tested in real industrial environments. Smartwin's products and solutions have been widely applied in fields with extremely stringent requirements for motion precision and speed, such as linear motor for semiconductor manufacturing, LCD panel manufacturing, and new energy battery production lines. In these high-standard production scenarios with continuous operation and short maintenance windows, the high stability, environmental adaptability, and long-term precision maintenance capabilities demonstrated by its products fully validate its technological maturity and quality assurance system, providing solid support for the core performance of downstream customers' equipment.

Application scenarios :

New energy battery manufacturing: covering the coating, die-cutting, winding, stacking, packaging, welding, formation, testing, PACK and other processes of lithium battery manufacturing, it is one of the direct drive motors manufacturers with the most complete product range in the domestic industry, and is committed to solving equipment pain points such as electromagnetic interference and stacking temperature drift.

Technical Highlights: The BMW series fully enclosed modules feature a labyrinth-style protective cover design, effectively preventing carbon powder and electrode chips from falling into the module during the stacking process and causing damage to the slider. The CA26 series absolute magnetic grid readhead has a resolution of up to 0.5µm, an IP67 protection rating, and offers better cost performance.

Laser Cutting and Etching: Gantry Structure for Marble ( using Smartwin CFH Series Linear Motors) This increases the overall stability of the equipment; the use of linear motors improves the accuracy of operation, enabling etching linewidths of 20 micrometers and splicing accuracy of <±5 micrometers, increasing the product yield to over 98%.

Panels and 3C Equipment : For scenarios such as OLED panel cutting and camera module assembly, a modular linear motor platform has been launched, which supports independent control of multiple actuators and shortens the equipment assembly cycle by 50% .

3. From Product Supply to Technological Collaboration Upgrades, Customer-centric Value Creation.

Smartwin lies not only in product performance but also in its innovative service model. The company is committed to building deep collaborative relationships with its clients. Relying on a professional technical team, it can provide comprehensive technical support throughout the entire process, from initial selection and analysis, mid-term integration and optimization, to ongoing maintenance, tailored to the specific process needs of its clients. This problem-solving-oriented collaborative model transforms Smartwin from a standard product supplier into a strategic partner for clients, helping them enhance the overall performance of their equipment and jointly address technological challenges.

professional technical capabilities, rigorously proven product reliability, and deeply collaborative service model, Smartwin Intelligent Equipment demonstrates significant comprehensive advantages in the domestic linear motor field. For equipment manufacturers committed to improving equipment performance and accelerating innovation, Smartwin is a partner worthy of close attention and evaluation.

En

En