An In-Depth Introduction to Smartwin Encoder

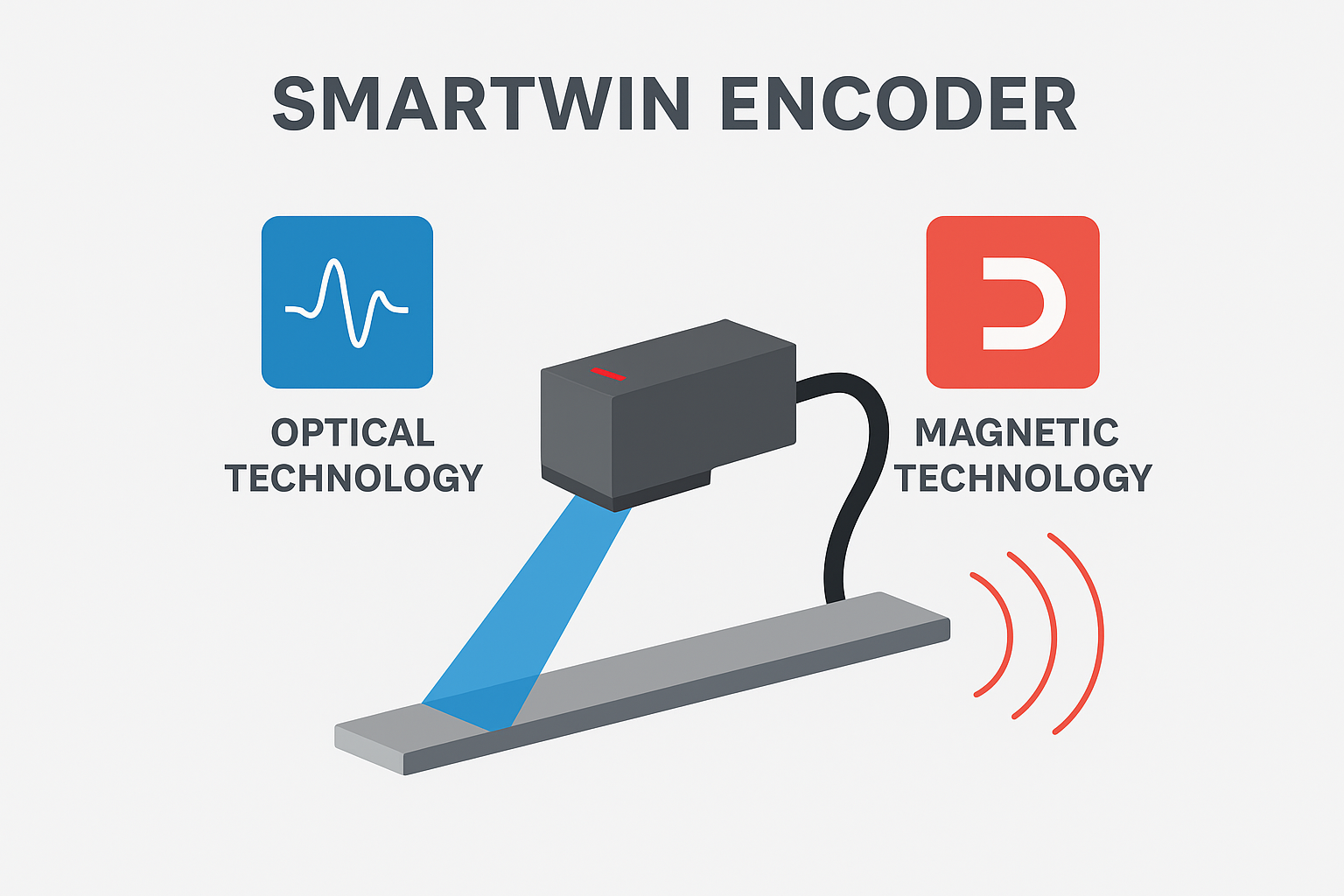

Encoders are the heartbeat of modern motion control systems. Whether in automation, CNC machining, laser processing, or woodworking, precise feedback is essential for accuracy, reliability, and efficiency. Among the many encoder solutions available today, the Smartwin Encoder stands out as a compact yet powerful device that combines optical and magnetic technologies to deliver exceptional performance across diverse applications.

What Is the Smartwin Encoder?

The Smartwin Encoder is an advanced motion feedback system designed to measure and control position and speed in linear and rotary applications. Unlike standard encoders that may focus solely on one sensing method, Smartwin integrates the strengths of optical and magnetic encoder designs, creating a versatile and reliable solution for industrial environments.

Its unique features—such as a LED-indicated readhead, compact design, high precision, wide assembly gap tolerance, and resistance to environmental variations—make it a top choice for manufacturers seeking both accuracy and durability.

The Importance of Encoders in Modern Automation

To appreciate what the Smartwin Encoder offers, it's important to understand the broader role of encoders. In automation and robotics:

Encoders convert motion into readable signals for control systems.

They provide feedback on position, velocity, and direction of moving parts.

They enable closed-loop systems that ensure precision and efficiency.

They help minimize errors, waste, and downtime in production lines.

Without reliable encoders, systems like CNC machining centers, robotic arms, and laser cutters would not achieve the precision and repeatability required in today's competitive industries.

Smartwin Encoder Features in Detail

Readhead Advantages

The readhead is the brain of an encoder system, and Smartwin's readhead is engineered with performance and usability in mind:

LED indicator – Provides real-time status visibility, simplifying installation and troubleshooting.

Small size – Compact enough to fit into limited spaces, supporting sleek machine designs.

High precision – Supports demanding motion control applications that require micron-level accuracy.

Multiple resolutions – Flexible options to match application requirements, from coarse to ultra-fine motion control.

Wide application adaptability – Works effectively in automation, robotics, and machining systems.

Optical Encoder Capabilities

Optical encoders are well-known for their high resolution and accuracy. Smartwin's optical encoder offers:

Diversity of pitch – Different scale pitches available to meet varying accuracy needs.

Micron-level positioning – Suitable for industries like semiconductor manufacturing and laser cutting.

Non-contact sensing – Reduces wear and extends the encoder's operational life.

Magnetic Scale Benefits

The magnetic side of Smartwin encoder ensures durability and reliability in harsh environments:

High-performance magnets – Provide strong, stable signals even in dusty or oily conditions.

Temperature insensitivity – Delivers consistent results despite environmental fluctuations.

Rugged reliability – Perfect for woodworking, heavy machinery, and outdoor automation systems.

Operational Advantages

Beyond sensing technologies, Smartwin encoders shine in overall usability:

Fast response time – Ensures real-time accuracy for dynamic processes.

Large assembly gap – Simplifies installation and reduces downtime.

No mechanical gap – Provides smooth operation and eliminates backlash.

Low maintenance – Reduces operating costs over the product lifecycle.

Smartwin Encoder Compared with Other Encoder Types

To understand the true value of Smartwin Encoder, let's compare it with other encoders typically used in automation:

| Feature | Optical Encoder | Magnetic Encoder | Smartwin Encoder |

|---|---|---|---|

| Precision | High | Medium to High | High (combines both) |

| Durability | Low (sensitive to dust/oil) | High | High |

| Assembly | Requires tight tolerance | More flexible | Very flexible (large gap) |

| Environmental Resistance | Moderate | Strong | Excellent |

Clearly, Smartwin Encoder integrates the best of both worlds—delivering precision and robustness without compromise.

Application Fields of Smartwin Encoder

Automation Industry

Automation relies heavily on motion control. The Smartwin encoder helps achieve:

Precise robotic arm positioning.

Accurate speed feedback in conveyor systems.

Reliable control in pick-and-place machines.

Laser Industry

Laser processing demands extreme accuracy. Smartwin encoders enable:

Stable, precise motion for laser cutting and engraving.

Consistent beam positioning in high-speed applications.

Improved quality and reduced material waste.

Machine Tool Industry

In CNC machining, even a micron-level error can result in defective products. Smartwin encoders support:

Precision milling and turning.

Consistent performance in multi-axis machining centers.

Feedback integration for advanced closed-loop systems.

Woodworking Industry

Woodworking involves environments filled with dust and vibration. Smartwin encoders thrive here due to:

Magnetic resilience against dust and debris.

Stable performance on saws, routers, and sanding machines.

Improved finish quality and reduced rework.

Installation and Best Practices

To maximize performance, correct installation is essential. Here are best practices:

Use the LED indicator to align the readhead properly.

Take advantage of the large assembly gap to ease installation.

Ensure that the scale is clean before setup to avoid errors.

Integrate with modern PLC systems for maximum efficiency.

Following these guidelines ensures that the Smartwin Encoder operates at peak performance from day one.

The specific maintenance method should follow the instructions provided in the original manufacturer's maintenance manual.

Advantages of Smartwin Encoder

Compact yet powerful – Fits modern machine designs.

Cost-effective – Long lifespan reduces replacement costs.

Multi-technology design – Combines optical and magnetic benefits.

Industry versatility – From automation to woodworking.

Future-proof – Ready for integration with Industry 4.0 systems.

Challenges and Considerations

While Smartwin encoders offer many benefits, users should be mindful of:

Ensuring compatibility with legacy systems.

Training technicians on hybrid optical-magnetic features.

Balancing cost with required resolution and application needs.

Future of Encoders and Smartwin's Role

The future of encoders is tied closely to automation, robotics, and AI-driven manufacturing. As systems demand higher speeds, greater accuracy, and smarter integration, the Smartwin Encoder is positioned as a forward-looking solution. Its hybrid design, compact size, and adaptability make it ideal for Industry 4.0 and beyond.

Conclusion

The Smartwin Encoder is not just another motion feedback device. It is a carefully engineered solution that bridges the gap between optical precision and magnetic durability. Its LED-indicated readhead, compact form, fast response, and temperature stability make it a standout choice for industries ranging from automation and laser cutting to CNC machining and woodworking.

For businesses seeking a reliable, high-performance, and future-ready encoder, the Smartwin Encoder delivers precision, resilience, and value—helping engineers and manufacturers achieve more with less effort.

En

En