In the evolving world of precision motion control, linear motors have become a cornerstone for industries seeking speed, accuracy, and reliability. Linear motors provide direct linear motion without the use of mechanical transmission elements, offering a superior alternative to traditional systems reliant on belts, gears, or screws. Among the players in this specialized field, Smartwin Motor stands out as a premier supplier of high-performance linear motor solutions.

With a robust foundation in innovation, engineering excellence, and a customer-centric approach, Smartwin has developed a diverse portfolio that addresses the nuanced requirements of modern automation, semiconductor, life sciences, and precision machinery industries. This guide offers a comprehensive look at Smartwin's linear motor offerings, their advantages, application areas, and how to select the ideal motor for your needs.

What Is a Linear Motor?

A linear motor is an electric actuator that generates straight-line motion directly from electromagnetic forces. In essence, it is a rotary motor that has been “unrolled” to produce linear instead of rotary output. The motor consists of two main parts:

Forcer (primary): Contains coils that generate a magnetic field.

Platen (secondary): Usually fitted with magnets or a magnet track.

When current is applied to the coils in the forcer, a magnetic field interacts with the magnets in the platen, creating motion. This motion is linear and direct, bypassing the need for intermediary components like screws or belts, resulting in zero mechanical backlash, improved responsiveness, and higher reliability.

How Linear Motors Work

The principle of operation is based on Lorentz force law, which describes the force on a charged particle in an electric and magnetic field. In linear motors:

Electric current flows through the forcer (typically in a three-phase configuration).

The current produces an alternating magnetic field.

This field interacts with the permanent magnets in the platen.

A direct, linear force is generated along the axis of motion.

This method allows for a very smooth, precise, and fast actuation with minimal mechanical wear.

Types of Linear Motors Offered by Smartwin

Smartwin offers a complete lineup of linear motors to meet diverse industrial requirements. Here are the key types:

1. Iron-Core Linear Motors (e.g., CUM Series)

Applications: CNC machinery, packaging systems, general automation

Iron-core linear motors from Smartwin are built for high thrust and robust thermal performance. Their laminated iron core enhances the force-to-size ratio, making them ideal for heavy-duty applications that demand high continuous and peak forces.

Features:

High force density

Efficient heat dissipation

Cost-effective in terms of force per dollar

Suitable for high acceleration and deceleration cycles

Technical Highlights:

Continuous force: 65 N to 1200 N

Peak force: Up to 2750 N

Optional water-cooling system for thermal-intensive applications

Limitations:

Presence of cogging force due to the iron core, which may cause slight velocity ripple

2. Ironless (Coreless) Linear Motors

Applications: Semiconductor, medical devices, optics, precision metrology

Smartwin's ironless linear motors offer ultra-smooth motion with zero cogging, thanks to the absence of iron in the forcer. This design eliminates magnetic attraction to the platen, resulting in virtually frictionless travel and better dynamic response.

Features:

No cogging or hysteresis

Lightweight, ideal for high-speed applications

Compact and efficient design

Technical Highlights:

Positioning accuracy: Within ±1 µm

Peak force: 50 N to 600 N

Excellent for cleanroom or lab environments due to low particle generation

Limitations:

Lower thrust output compared to iron-core motors

Higher cost per unit force

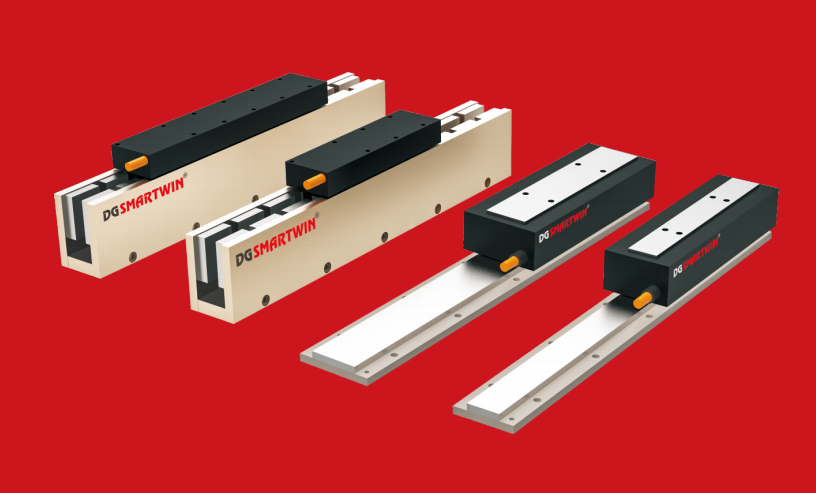

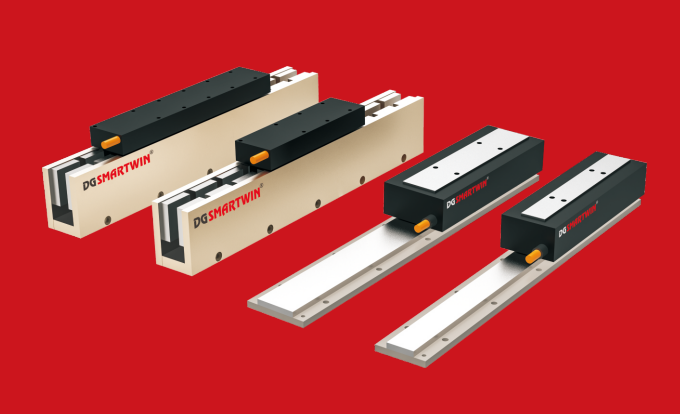

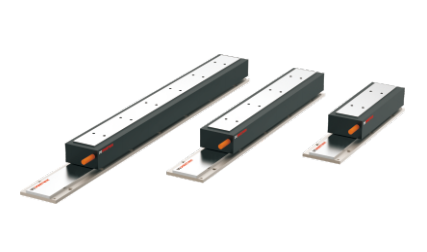

3. Linear Servo Motor Modules

Applications: Pick-and-place machines, printing, high-speed inspection systems

Smartwin also provides pre-assembled linear motor modules that include:

Linear motor (iron-core or ironless)

Integrated encoder

Optional guide rails or bearings

Aluminum baseplate for mounting

Benefits:

Turnkey plug-and-play motion systems

Simplified integration

Shorter development cycles for OEMs

These modules are ideal for developers who want high-performance motion without dealing with integration challenges.

Advantages of Smartwin Linear Motors

Smartwin's linear motor solutions offer significant benefits across a variety of operating conditions and industries:

High Speed and Acceleration

Linear motors can achieve extremely high speeds (up to several meters per second) and accelerations (over 10G) due to the direct drive nature and low moving mass.

Precision and Repeatability

These motors provide sub-micron level positioning accuracy and excellent repeatability, making them ideal for advanced manufacturing processes.

Long Lifespan and Low Maintenance

With no mechanical contact, there is minimal wear, ensuring extended life and reduced maintenance needs.

Compact and Scalable Design

Linear motors are compact and scalable, fitting into tight spaces or modular setups, perfect for flexible and compact machine architectures.

No Backlash or Compliance Issues

The absence of mechanical transmission elements means no backlash, increasing motion fidelity and control.

Application Industries

Smartwin's linear motors have been successfully deployed across multiple high-precision industries. Let's explore these in detail:

Semiconductor Manufacturing

Wafer dicing and cutting: High thrust motors with micron-level precision

Die bonding and packaging: Ultra-smooth ironless motors prevent substrate damage

AOI and alignment systems: Integrated modules for optical inspection

Medical & Life Sciences

Robotic surgery and diagnostic imaging: Quiet, accurate, and smooth linear motion

Liquid dispensing and sample handling: Repeatable and sterile operation

Brain slice analysis: ±1 µm resolution to detect fine neural changes

Industrial Automation

High-speed pick-and-place machines

Vision inspection systems

Battery manufacturing and assembly lines

Laser and Optics

Laser cutting and engraving: Consistent linear speed for even material removal

Lens positioning and focusing: High resolution and vibration-free motion

Digital Printing

UV and textile printers: Uniform, high-speed movement for quality prints

3D printing: Precision layering with minimal vibration

Key Considerations When Choosing a Linear Motor

When selecting a linear motor, consider the following factors to ensure optimal performance and cost-efficiency:

1. Stroke Length

Defines how far the motor needs to move. Linear motors can handle from a few millimeters to several meters depending on design.

2. Load Requirements

Determine the moving mass or external force that needs to be countered.

3. Speed and Acceleration

Application speed dictates the need for either high-force iron-core or fast-response ironless motors.

4. Precision

Higher accuracy applications may require ironless motors and higher-resolution encoders.

5. Cooling

Consider air or water cooling based on the duty cycle and thermal load.

6. Environmental Conditions

Temperature, humidity, and cleanliness all affect motor choice. Ironless motors are preferred in cleanrooms.

7. Budget

While ironless motors offer better precision, they are more expensive. Match motor performance to cost constraints.

Why Choose Smartwin Motor?

Smartwin has established itself as a technology-driven, quality-oriented, and customer-focused motion control manufacturer. Here are compelling reasons to trust us:

R&D Innovation: Over 90+ valid patents, including 16 for inventions

Certifications: ISO 9001, ISO 14001, and ISO 45001

Global Footprint: Active projects in Asia, Europe, and the Americas

Turnkey Solutions: Motor + Encoder + Servo Drive available as packages

Engineering Support: Customization and co-development for OEMs

Exhibition Recognition: Multiple awards at SNEC, WIN EURASIA, and Electronica Munich

Getting Started with Smartwin Linear Motors

Ready to upgrade your motion system? Smartwin offers detailed datasheets, CAD models, application notes, and technical support to help you specify the best motor for your needs.

Contact Options:

Explore product categories: https://www.zhiyingmotor.com

Request engineering support or sample units

Schedule a free consultation with a motion expert

Conclusion

Smartwin's linear motors offer a winning combination of high precision, reliability, and modular flexibility. Whether you're designing the next generation of semiconductor tools or streamlining your automation line, we have motors tailored to your exact performance and integration needs.

Stay ahead of the curve in motion control technology. Choose Smartwin—where precision meets power.

Related Reading

Iron-Core vs. Ironless Motors: What's Best for Your Application?

Top 5 Linear Motor Trends in 2025

How to Integrate Encoders with Linear Motors

Servo Modules vs. Custom Integration: A Comparison

En

En