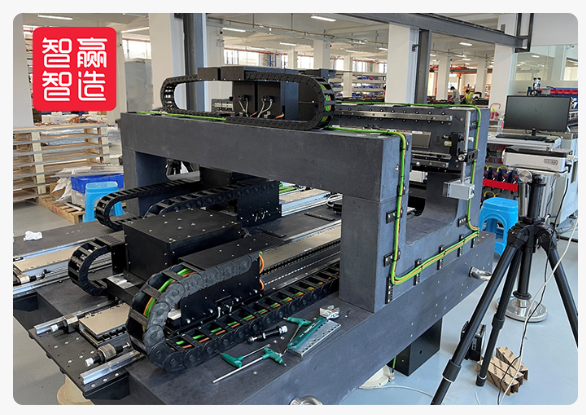

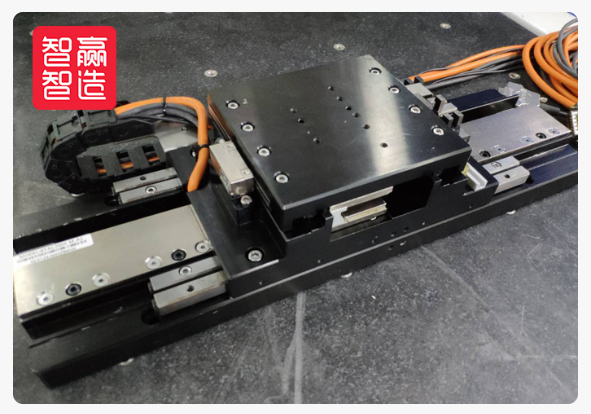

When high-speed precision, smooth motion, and zero cogging are critical to success, ironless linear motors are often the go-to solution. Unlike iron-core motors, which contain laminated steel to increase force density, ironless motors eliminate magnetic attraction and cogging effects entirely. This allows for ultra-smooth, vibration-free motion—an essential characteristic for applications that demand high positioning accuracy and responsiveness. Zhiying Motor (Smartwin) is a leading manufacturer of advanced linear motion systems, offering a high-performance line of ironless linear motors engineered for dynamic, clean, and precise operations. In this article, we highlight the top five applications where Zhiying's ironless motors are redefining performance standards.

1. Semiconductor Wafer Handling and Packaging

Why It Matters

In semiconductor fabrication, extreme precision and particle control are mandatory. Processes like wafer dicing, die bonding, and optical alignment require equipment that can operate with nanometer-level precision and zero mechanical backlash. Even minimal vibrations can reduce process yield or damage fragile substrates.

How Zhiying Ironless Motors Excel

Cogging-free motion ensures smooth trajectory control, critical for optical systems and clean wafer placement.

High dynamic responsiveness allows for fast pick-and-place cycles.

Compatible with high-resolution encoders for closed-loop feedback and fine positioning.

Typical Use Cases

Wafer transport and alignment stages

Chip packaging and inspection equipment

Precision robotic arms for die placement

Key Benefit: Increased yield, better process stability, and enhanced equipment longevity in cleanroom environments.

2. Medical Imaging and Diagnostic Equipment

Why It Matters

Medical devices often require silent, smooth, and repeatable movement to perform accurate diagnostics or minimally invasive operations. For example, brain imaging, cell analysis, and surgical scanning platforms cannot tolerate erratic motor motion or thermal drift.

Why Zhiying Ironless Motors Are Ideal

No magnetic attraction between forcer and platen, eliminating jitter during motion.

Excellent thermal control—generating low heat even under continuous operation.

Compact form factors allow for integration in confined medical instrumentation.

Typical Use Cases

Brain slice scanning systems

Automated liquid analysis and blood diagnostics

Sample positioning in X-ray or PET scanners

Key Benefit: Quiet and precise operation enhances diagnostic reliability and patient comfort.

3. Optical Inspection and Precision Metrology

Why It Matters

Whether inspecting semiconductor wafers, PCBs, or precision lenses, repeatable scanning motion is essential. Surface anomalies can be missed or misinterpreted if motion is uneven, and system resolution is directly tied to the stability of the motion platform.

Zhiying's Advantages

Low moving mass enables rapid acceleration and deceleration with minimal overshoot.

Consistent velocity eliminates blur during camera or laser-based inspections.

Integrates with vision systems for real-time positioning feedback.

Typical Use Cases

Automated Optical Inspection (AOI)

Surface profile scanning

Lens testing and calibration stations

Key Benefit: Higher defect detection rates and faster inspection times with ultra-stable scanning motion.

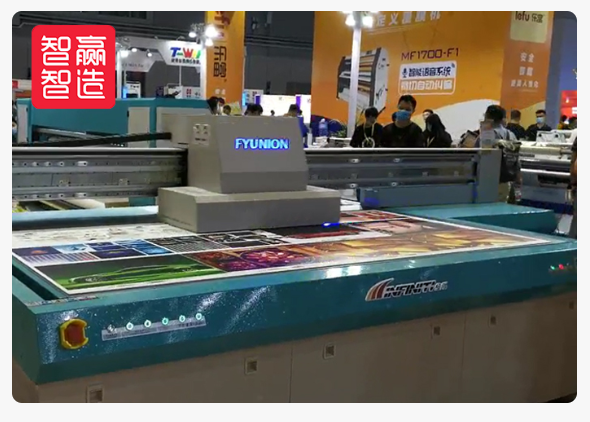

4. High-Precision 3D Printing and Micro-Additive Manufacturing

Why It Matters

In micro-scale additive manufacturing—such as 3D printing of electronics or bioprinting—deviation in head movement can cause deformation, misalignment, or nozzle clogging. Linear motors must support ultra-precise deposition with consistent motion across axes.

How Zhiying Delivers

Smooth acceleration profiles minimize vibration and structural resonance.

Optimized for short-stroke, high-frequency linear movements.

Low inertia design allows tight control over start/stop sequences.

Typical Use Cases

High-resolution resin and DLP 3D printers

Microfluidic device fabrication

Bio-ink or cell printing platforms

Key Benefit: Increased build accuracy, reduced material waste, and compatibility with clean lab environments.

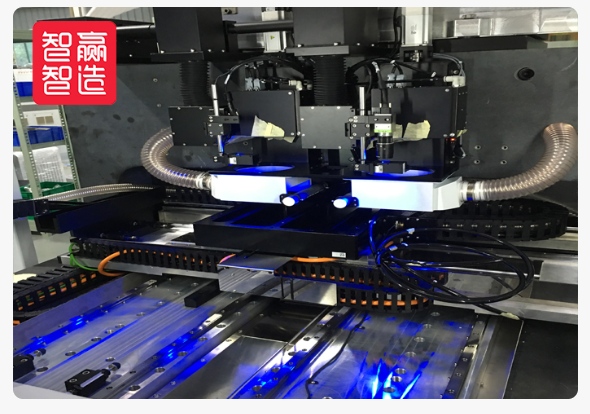

5. Laser Processing and Ultra-Fine Cutting

Why It Matters

Applications such as laser micromachining, stent cutting, and etching require precise movement of the laser head or workpiece. Motion inconsistencies can lead to rough edges, uneven exposure, or compromised part quality.

Zhiying's Capabilities

Zero-cogging force allows for smooth path following.

Integrated with high-resolution encoders for sub-micron feedback control.

Lightweight assembly supports fast, jitter-free laser head travel.

Typical Use Cases

UV laser etching on PCBs

Thin-film scribing and patterning

Medical stent cutting or catheter slotting

Key Benefit: Cleaner, more precise cuts with reduced tooling wear and consistent laser output.

Why Choose Zhiying Ironless Linear Motors?

Zhiying's ironless motors combine technical innovation with real-world application knowledge to deliver solutions that outperform traditional linear actuators in challenging environments.

Key Features:

No cogging or magnetic pull, ensuring consistent velocity and trajectory

Lightweight and compact for smaller motion systems

Efficient heat management for continuous high-performance operation

Plug-and-play integration with encoders and drivers

Industries Served:

Semiconductor & Electronics

Medical & Life Sciences

Precision Optics & Metrology

Advanced Manufacturing

Laboratory Automation

With decades of engineering experience and over 90+ patents, Zhiying Motor is a trusted partner for global OEMs and system integrators.

Conclusion

From wafer dicing to bioprinting, ironless linear motors are enabling the next generation of precision machines—where every micron counts. Zhiying's advanced engineering, reliable performance, and modular product offerings make it easier than ever to integrate high-performance motion control into your system.

If your project demands vibration-free, high-accuracy, and clean linear motion, Zhiying's ironless linear motors are the answer.

En

En