Core Difference Analysis of SMARTWIN CJM080 and CJM100 Series

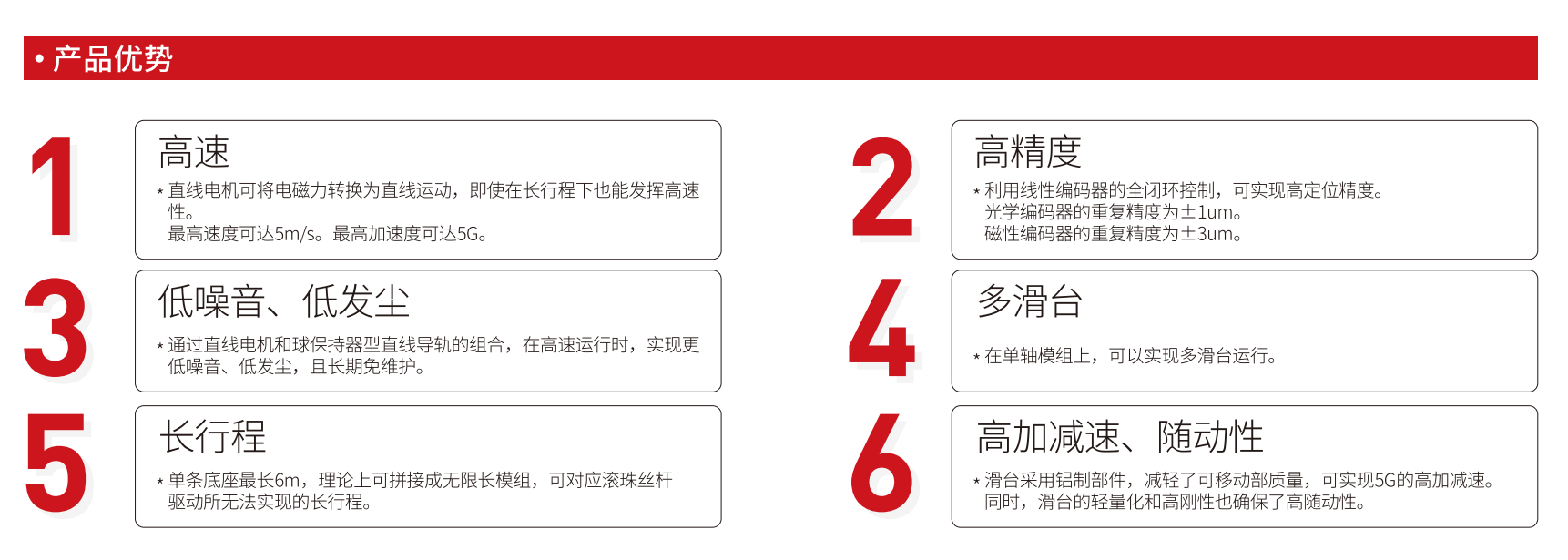

As a highly efficient solution for small-scale precision automation, the CJM Series is widely acclaimed for its core advantages of compact size, stable operation, and easy installation. The core differences between the CJM080 and CJM100 Series lie in load adaptation gradients and power output levels, forming a product matrix that precisely caters to the needs of different application scenarios.

In terms of core parameters, although both series fall within the scope of 4 models in the product family, the CJM080 is an ultra-compact space optimization expert, with a maximum mover width of 100mm, matching a stator width of 100mm. By contrast, the CJM100 builds on the foundation of the CJM080, expanding the maximum mover width to 125mm, with the corresponding stator width also increased to 125mm. Larger dimensions translate to stronger thrust: the peak continuous thrust of the CJM100 can reach more than 1 time that of the CJM080, enabling it to drive heavier loads.

Targeted optimizations in technical design form the core support for the differences between the two series. Both products adopt the classic iron-core low cogging design of the CJM Series, but their optimization directions are tailored to different power requirements. The CJM080 Series focuses on compactness and low energy consumption, achieving an ultra-thin and ultra-short body design through a streamlined magnetic circuit structure. While ensuring operational stability, it is more suitable for light-to-medium precision equipment with extremely limited installation space. The CJM100 Series, on the other hand, prioritizes high rigidity and power stability, enhancing the structural strength of the body and adopting high-wear-resistant insulating materials, which allows it to maintain stable performance during continuous high-load operation. In terms of installation compatibility, both series feature easy installation, but the CJM100 Series has optimized the layout of fixing holes for heavy-load requirements, supporting more stable multi-directional installation methods to adapt to heavy-duty working conditions with high-frequency start-stop operations.

The precise segmentation of application scenarios further highlights the positioning differences between the two series. With moderate power and a compact size, the CJM080 Series is widely used in light-to-medium load scenarios such as micro-connector assembly, precision inspection of surface mount components, and pin inspection of small chips. Its continuous thrust range of 175-349N can accurately meet the driving needs of micro-actuator components. The CJM100 Series is designed for scenarios with higher power demands, such as the drive of placement heads in small SMT chip mounters, precision assembly of MEMS sensors, and heavy-load handling of small wafers. Its maximum continuous thrust of 447N can stably drive heavy-load actuator mechanisms, and combined with its high-rigidity design, it achieves a balance between precision and efficiency in working conditions such as high-speed chip mounting and heavy workpiece transfer. Together, they form a complete solution for SMARTWIN Intelligent Manufacturing in the field of small-scale precision automation, ensuring that you can find a perfectly suited product no matter what your requirements are.

En

En