Walking through the workshop of Smartwin Intelligence, one won't see grand assembly lines—only precision assembly stations, testing instruments, and laser etching equipment. Engineers are debugging the latest generation of encoders, with data flickering on the screens accurate to the micrometer level.

Here, no one talks about "disruption" or "industry trends"; instead, they prefer to discuss "precision," "stability," and "customer-specific processes." It is this down-to-earth attitude of focusing on the real economy and dedicated efforts in niche segments that has enabled Smartwin to gradually pave its way from technological substitution to brand breakthrough over the past decade.

"Keeping China's intelligent equipment on par with global standards" is not just a mission printed in Smartwin corporate brochure, but a guiding principle for its development. As a national-level "Little Giant" enterprise specializing in cutting-edge and sophisticated technologies, Smartwin Intelligence has focused on the direct-drive track for a decade, "forging" a "sharp edge" at the micrometer scale. It has successfully independently developed linear motors, torque motors, drivers, and grating encoders, improving positioning accuracy to within ±2 micrometers approximately 1/40 the diameter of a human hair and achieving full autonomy in the closed-loop core technology of direct-drive systems. It has not only broken the overseas technological monopoly but also become a key "breaker of barriers" in the process of advancing the independent and controllable development of China's high-end equipment.

A decade of forging to sharpen a single sword: transitioning from trade to achieving technological breakthroughs

In 2013, Liu Yangsheng, who had been engaged in trade in the industrial automation sector, keenly detected the emerging demand for precision motion control in China's high-end equipment. He abandoned his trade business, founded Smartwin Intelligence, and invited Wang Huohua—who specialized in linear motor technology R&D—to join the company, resolutely committing himself to the independent R&D of linear motors.

Smartwin Intelligence encountered numerous difficulties during its initial "from 0 to 1" stage, ranging from technological breakthroughs and market development to team building and capital turnover. Particularly in its darkest hour, the team rushed around to secure an emergency financing of 3 million yuan, only to face repeated setbacks, plunging the company into severe financial pressure and a survival crisis. However, it was precisely such hardships that made the company's management clearly realize: only by continuously consolidating internal management and adhering to product innovation can the enterprise truly remain invincible in the fierce market competition.

Thanks to this perseverance, Smartwin Intelligence finally achieved a breakthrough. In 2015, merely two years after the company's establishment, it launched China's first ultra-thin linear motor with high thrust density. This product not only gained immediate access to the market but also successfully entered the supply chain systems of a number of leading equipment enterprises—most of these cooperative relationships have continued to this day. Relying on the success of this product, Smartwin Intelligence gradually secured a firm foothold in the industry.

The success of its products has injected confidence into Smartwin Intelligence's development. Since 2017, the company has entered a virtuous cycle of sustained profitability. Its operating income has grown steadily from approximately 20 million yuan to over 200 million yuan in 2024, representing a nearly tenfold increase over seven years and demonstrating a clear and stable growth trajectory.

What is Direct Drive? The Technological Leap Behind Micrometer-Level Precision

After crossing the "valley of death" in entrepreneurship, how to identify the right niche track to achieve new breakthroughs has become a new proposition for Smartwin Equipment. Amid fierce market competition, the company has adopted a differentiated competition strategy: by focusing on niche segments in the direct-drive motor industry, it provides comprehensive solutions tailored to customer needs.

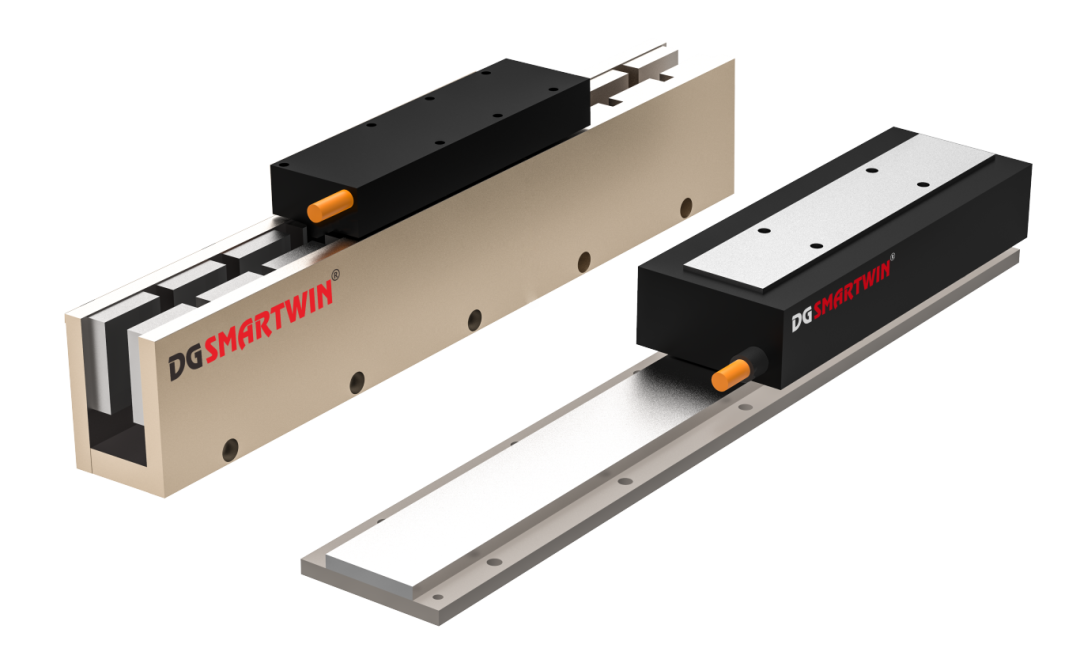

What is direct drive? And what advantages does it have compared with traditional servo motors? Tan Xiaopeng, Director and Board Secretary, explained it with a down-to-earth analogy: "A traditional servo motor is like a conventional bicycle, where power needs to be transmitted through a chain; a direct-drive motor, however, is like an electric bicycle that outputs power directly—offering faster response, more precise control, and lower noise." This technology eliminates issues such as backlash, wear, and precision degradation in mechanical transmission, enabling precision control at the micrometer and sub-micrometer levels. For instance, in lithium battery coating, it can control the thickness error of electrode sheets within ±2 μm.

However, achieving technological breakthroughs in direct-drive systems is no easy feat. For a long time, the three core components of such systems—motors, drivers, and encoders—have been monopolized by international brands from Japan, the United States, Israel, Singapore, and other countries. In particular, high-performance drivers and grating encoders have extremely high technical barriers, making them key bottlenecks restricting domestic substitution.

To break through this predicament, Smartwin Intelligence has continued to tackle key challenges. In 2021, the company launched the AKS series drivers with fully independent intellectual property rights, and achieved mass sales in the second half of the following year. In 2022, its self-developed grating encoders successfully entered mass production, boasting a maximum resolution of 0.05 micrometers and a maximum repeat positioning accuracy of ±0.1 micrometers—with key technical indicators on par with those of leading international brands.

Today, Smartwin Intelligence has become one of the few enterprises in China that simultaneously masters the three core technologies of motors, drivers, and encoders, and possesses full-link capabilities from core components to system integration. Its linear motor modules deliver outstanding performance, including repeat positioning accuracy within ±2 micrometers, a maximum speed of 5 m/s, and an acceleration of 10G. These products are widely used in high-end production equipment of many well-known first-tier manufacturers in fields such as lithium batteries, flat-panel displays, semiconductors, and 3C (computers, communications, and consumer electronics).

From realizing import substitution to venturing into cutting-edge fields, Smartwin is advancing from a "hidden champion" in domestic niche segments to the international competitive stage, emerging as a crucial force in promoting the independent and controllable development of core technologies for China's intelligent equipment.

This article is sourced from the Dongguan Daily Website

En

En