Why Maintenance Matters in Precision Sensing

Linear optical encoders are at the heart of today's precision manufacturing, automation, and metrology systems. From CNC machining and semiconductor wafer inspection to robotic assembly and medical imaging, these devices provide the micron-level accuracy that modern industries demand. However, to maintain this accuracy over years of continuous operation, proper maintenance and calibration practices are essential. Neglecting encoder upkeep can lead to measurement drift, loss of resolution, premature wear, and ultimately, costly downtime.

This article explores in detail the best practices for maintaining and calibrating linear optical encoders, ensuring reliability and long-term performance. Along the way, we'll cover topics such as optical linear encoder principle, incremental vs. absolute systems, calibration procedures, cleaning protocols, and troubleshooting.

Understanding the Basics of Linear Optical Encoders

Before diving into maintenance strategies, it's important to revisit the principle of operation.

What is a Linear Optical Encoder?

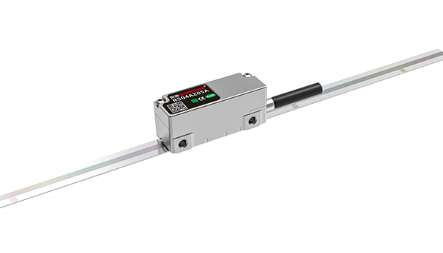

A linear optical encoder is a precision measurement device that converts linear displacement into digital or analog signals using light. It typically consists of:

A scale (glass or metal with a finely patterned grating).

A readhead containing LEDs, photodiodes, and signal processing electronics.

When light passes through or reflects off the scale’s grating, the interference pattern creates signals that correspond to position changes. These signals are processed into incremental or absolute position data.

Optical Linear Encoder Principle

The optical linear encoder principle relies on diffraction and photo-detection:

A light source projects onto the scale's grating.

Movement along the axis creates changes in the light pattern.

Sensors detect these changes and convert them into position signals.

Different encoder designs optimize this principle for speed, accuracy, or robustness.

Types of Linear Optical Encoders

Linear Optical Incremental Encoder – Provides relative position changes (requires a reference mark for homing).

Absolute Linear Optical Encoder – Delivers exact position data without homing, using unique code tracks.

Linear Optical Quadrature Encoder – Outputs A/B phase-shifted signals for direction and higher resolution.

Linear Actuator Optical Encoder – Integrated into actuators for real-time motion feedback.

Understanding these variations is essential for tailoring maintenance and calibration procedures.

Common Failure Modes and Maintenance Challenges

Even with high-quality construction, linear optical encoders face several challenges during their lifecycle:

Contamination by Dust, Oil, or Coolant

Manufacturing environments often expose encoders to particulates or liquids that can obstruct the optical path.

Scale Scratches or Abrasions

Mishandling during installation or cleaning can permanently damage glass or metal scales.

Thermal Expansion Effects

Temperature fluctuations cause material expansion or contraction, affecting encoder accuracy.

Signal Degradation

Aging LEDs, alignment drift, or cable damage may reduce signal integrity.

Electrical Noise Interference

Encoders may produce erroneous readings in high-EMI environments.

Recognizing these challenges helps set the stage for preventive maintenance practices.

Maintenance Best Practices for Linear Optical Encoders

Preventive Cleaning Procedures

Recommended Cleaning Tools

Use lint-free microfiber cloths, anti-static brushes, or compressed dry air.

For stubborn contamination, use isopropyl alcohol (IPA, 99%).

Scale Cleaning

Avoid excessive pressure. Wipe gently along the scale's length.

Never use abrasive materials.

Readhead Cleaning

Only if manufacturer guidelines permit.

Use soft swabs and minimal solvent.

Frequency

Clean in high-dust / oil environments every 3–6 months.

In cleanrooms, every 12–18 months may suffice.

Environmental Protection

Protective Seals and Covers

Install bellows or covers on linear stages to shield encoders.

Positive Air Pressure

In CNC or semiconductor equipment, direct clean air over the encoder scale to prevent contamination.

Vibration Mitigation

Use dampers or precision mounting to reduce long-term misalignment.

Handling and Storage Guidelines

Handle scales with gloves to avoid fingerprints.

Store encoders in anti-static, shock-protected packaging.

Avoid bending or twisting flexible scales.

Routine Inspection Checklist

Inspect alignment between scale and readhead.

Check signal strength with the diagnostic interface.

Examine cables and connectors for wear or loosening.

Verify environmental seals remain intact.

The specific maintenance method should follow the instructions provided in the original manufacturer's maintenance manual.

Calibration Best Practices

While maintenance keeps encoders functional, calibration ensures accuracy.

Why Calibration Matters

Corrects systematic errors like thermal drift or misalignment.

Validates encoder output against traceable measurement standards.

Ensures compliance with ISO 9001 and other quality standards.

Calibration Frequency

High-precision CNC / semiconductor tools: Every 6–12 months.

General industrial machinery: Every 1–2 years.

Critical aerospace / medical devices: Before and after major production runs.

Calibration Methods

Reference Artifact Method

Compare encoder readings against a calibrated laser interferometer.

Identify linearity errors.

Step Gauge Verification

Position encoder along fixed intervals using a gauge block or reference stage.

In-Situ Calibration

Many modern encoders feature self-calibration routines, using built-in reference marks or software compensation.

Thermal Compensation

Apply correction tables to account for temperature-dependent expansion.

Calibration Procedure

Ensure environmental stability (20°C ± 0.5°C, low vibration).

Mount encoder securely and remove contamination.

Perform initial zero-position reference.

Run encoder along its full travel using the chosen reference method.

Record deviations and apply compensation.

Document calibration data for audits.

Troubleshooting and Diagnostic Tools

Even with preventive maintenance, issues may arise. Effective troubleshooting minimizes downtime.

Common Issues & Fixes

No Signal Output

Check power supply, cable continuity, and grounding.

Weak or Fluctuating Signal

Clean scale/readhead, check alignment, replace aging LED source.

Noise in Position Data

Improve shielding, separate encoder cabling from high-power lines.

Missed Reference Marks

Re-align readhead or recalibrate reference index.

Diagnostic Tools

Oscilloscope – To monitor A/B quadrature signals.

Encoder Manufacturer Software – Displays real-time signal quality.

Laser Interferometer – For accuracy verification.

Multimeter – For cable continuity checks.

Future Trends in Encoder Maintenance and Calibration

Smart Encoders with Self-Diagnostics

New generations of linear absolute optical encoders integrate sensors for self-monitoring:

Signal health reporting.

Contamination detection.

Predictive maintenance alerts.

Remote Calibration via IoT

Encoders connected through Ethernet-based protocols (EtherCAT, PROFINET) will allow:

Remote calibration routines.

Cloud-based error compensation.

AI and Machine Learning in Feedback Systems

Machine learning algorithms will analyze historical encoder data to predict failure points and auto-correct measurement drift.

Protecting Accuracy Through Best Practices

Linear optical encoders play a critical role in precision manufacturing, robotics, and advanced automation. By following strict maintenance routines (cleaning, inspection, environmental protection) and adopting robust calibration practices (regular verification, compensation, and documentation), organizations can maximize uptime, reduce errors, and extend encoder lifespan.

As Industry 4.0 advances, future encoders will become smarter, self-calibrating, and connected, making maintenance more predictive than reactive. For now, disciplined best practices remain the surest path to ensuring high-speed systems continue to operate with micrometer-level precision.

En

En