Integrating a linear motor into a motion system isn't just about choosing the right motor—it requires coordinated integration with servo drives and encoders to unlock precision, stability, and full system performance. Whether you're building a pick-and-place machine, laser cutter, or semiconductor inspection stage, your motion control strategy hinges on seamless component compatibility.

In this guide, we walk through the best practices and essential considerations for integrating Smartwin's linear motors with servo drives and feedback encoders to create a robust, responsive motion system.

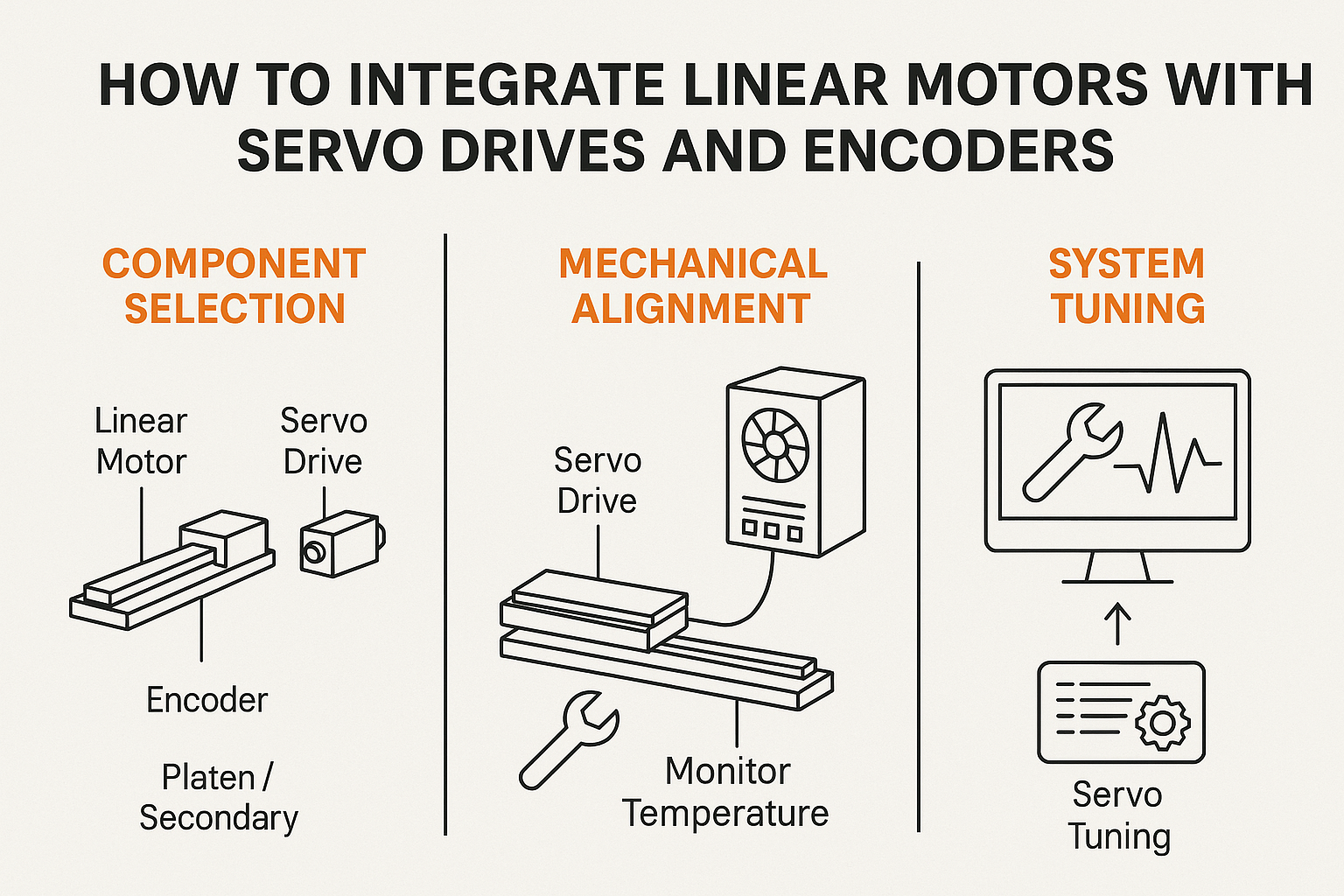

Understanding the Integration Triangle: Motor + Drive + Encoder

A linear motion system typically includes:

Linear Motor: Provides direct drive, high-speed linear movement (iron-core or ironless)

Servo Drive (Amplifier): Supplies current to the motor based on control signals

Encoder (Feedback Device): Measures position and velocity to close the feedback loop

These three components must be electrically and mechanically compatible, and properly configured in software.

Choosing the Right Linear Motor

Smartwin offers two main categories of linear motors:

Iron-Core Motors:

Higher thrust force

Best for heavy loads and industrial automation

Ironless Motors:

No cogging; smoother motion

Ideal for precision applications (semiconductor, optics)

Consider:

Stroke length

Required acceleration

Peak and continuous force

Mounting constraints

Selecting a Compatible Servo Drive

The servo drive (also called a motion amplifier) is responsible for powering the motor and executing control loops based on encoder feedback.

Key Parameters to Match:

Voltage and Current Ratings: Ensure the drive can handle the motor's continuous and peak current

Motor Type Support: Confirm the drive supports linear motors (not all rotary drives are compatible)

Feedback Interface: Drive must accept the encoder signal format (TTL, A/B/Z, SinCos, BiSS, etc.)

Recommended Drive Features:

Current and velocity loop tuning

Position control via external or internal controller

Safe torque off (STO) functionality

Smartwin motors are compatible with most mainstream industrial drives, including those from Delta, Yaskawa, Kollmorgen, and Beckhoff.

Encoder Selection and Mounting

Encoder Types:

Magnetic Encoders: Durable and compact; good for rugged environments

Optical Encoders: Higher resolution and accuracy; ideal for cleanrooms and metrology

Linear Gratings: Provide direct linear position sensing

Key Factors:

Resolution: Defines the smallest detectable position increment (e.g., 1 µm, 0.1 µm)

Interpolation: Some drives offer electronic interpolation for smoother feedback

Mounting Tolerance: Follow OEM specs for alignment and air gap

Best Practices:

Use shielded cables for encoder signals

Keep encoder cables separate from motor power lines

Verify signal compatibility between encoder and drive

Mechanical Integration and Alignment

Mounting:

Ensure the motor and encoder are mounted to a flat, rigid surface

Use alignment dowels or precision tooling holes if available

Maintain the specified air gap between the forcer and platen (especially for ironless motors)

Cables:

Allow for flex in dynamic applications (use drag chains)

Avoid tight bends or stress points

Secure connectors with vibration-resistant locks

Thermal Considerations:

Provide adequate heat sinking or active cooling if duty cycle is high

Monitor surface temperature during operation

Tuning the Motion System

Once the motor, drive, and encoder are physically installed and electrically connected, the system must be tuned.

Servo Tuning Steps:

Motor Identification: Load motor parameters into the drive (can be automatic or manual)

Feedback Configuration: Ensure encoder signal is correctly interpreted

Loop Gain Adjustment: Start with current loop, then velocity, then position

Filter Application: Add notch filters or low-pass filters to suppress resonance

Tools:

Use the drive's tuning software (Delta ASDA, Kollmorgen Workbench, etc.)

Run motion profiles to evaluate overshoot, settling time, and vibration

Testing and Validation

Before full deployment, run system validation checks:

Perform test cycles at various speeds and loads

Use oscilloscopes or data loggers to analyze position/velocity feedback

Monitor temperature and current draw over time

Key Performance Metrics:

Positional accuracy

Repeatability

Overshoot and settling time

System stability under load

Common Integration Challenges & Fixes

| Problem | Possible Cause | Suggested Fix |

|---|---|---|

| No motion | Miswired phases or feedback | Verify wiring and encoder polarity |

| Jitter or unstable movement | Gain too high / encoder noise | Reduce loop gain, check grounding |

| Overheating motor | Continuous load exceeds rating | Improve cooling, adjust duty cycle |

| Feedback loss | Loose cable or EMI interference | Secure connectors, use shielded cables |

Smartwin Support for Integration

we provide:

Motor datasheets with detailed electrical and mechanical specs

Encoder installation and alignment guidelines

CAD models for mounting design

Recommended drive pairings

Remote support for tuning and configuration

Pro Tip: When in doubt, request Smartwin's servo integration service to accelerate time-to-market and reduce setup errors.

Conclusion

Integrating linear motors with servo drives and encoders is the key to unlocking the full performance of a modern motion system. With proper component matching, careful mechanical design, and methodical tuning, Smartwin's linear motors can deliver industry-leading speed, precision, and reliability.

Whether you're building a high-speed pick-and-place robot or a micron-accurate metrology stage, Smartwin's engineering team is here to help you integrate with confidence.

Contact us at zhiyingmotor.com to start your integration journey today.

En

En